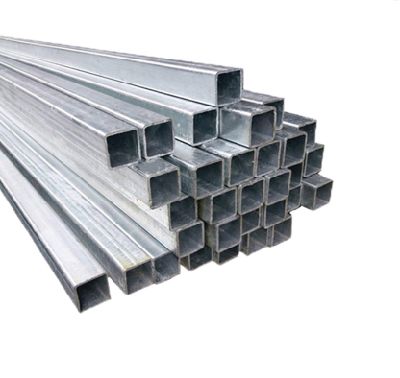

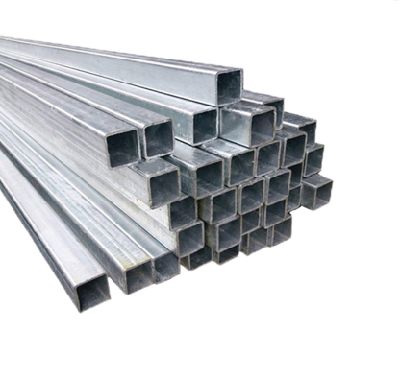

Outer Diameter: square 10*10-1000*1000mm rectangular:10*15-800*1100mm or as requested

Thickness: 0.8 - 12.75 mm or as requested

Length:12M, 6m, 5.8M, or as requested

Product Details

Outer Diameter | square 10*10-1000*1000mm rectangular:10*15-800*1100mm or as requested |

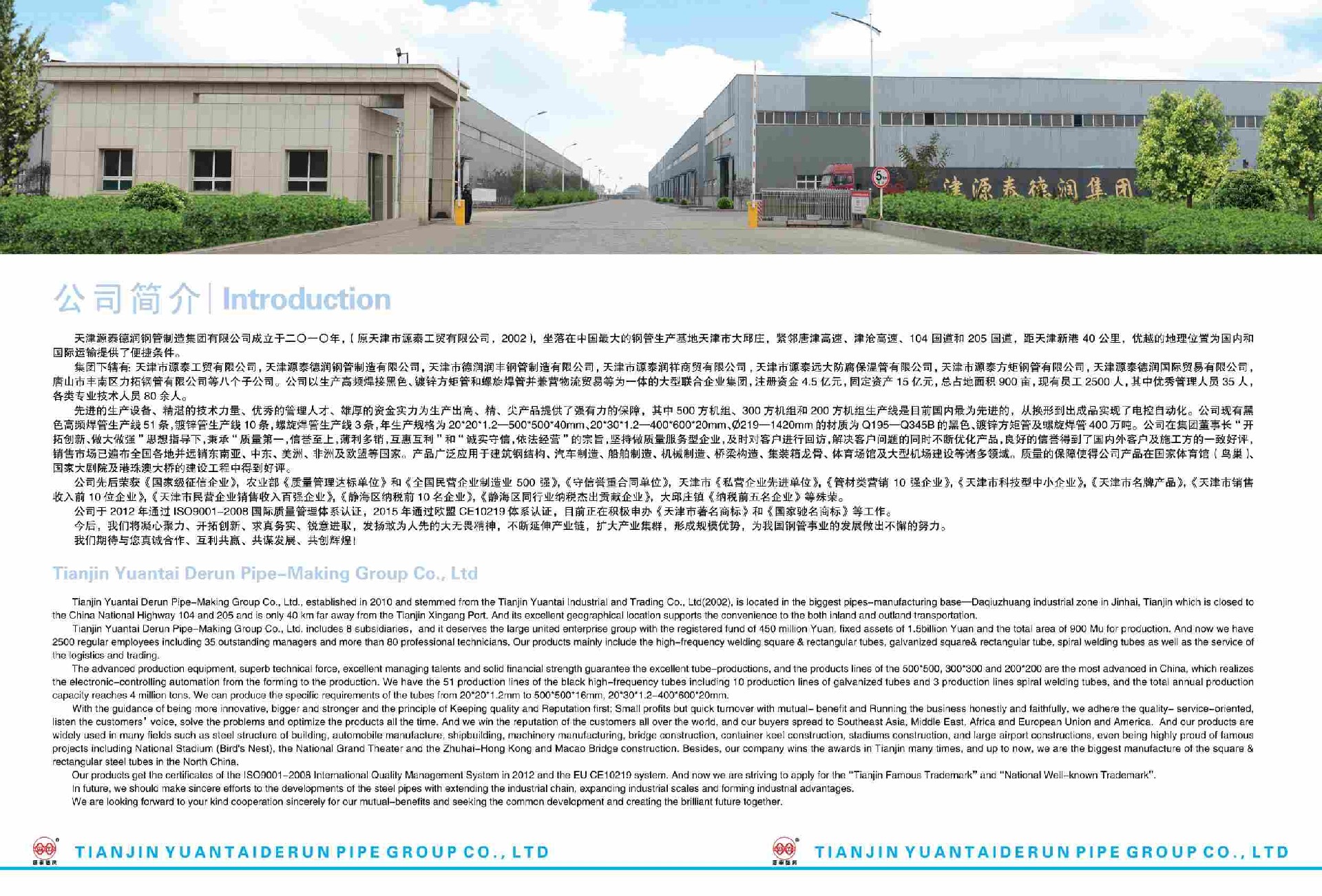

Galvanized square hollow sections (SHS) are structural steel components that are widely used in the construction industry. They are a type of steel tube that has been cold-formed to create a square or rectangular shape, with a hollow interior. The galvanization process involves coating the steel with a layer of zinc, which helps to protect it from rust and corrosion. This makes galvanized SHS a popular choice for outdoor applications where exposure to moisture and other environmental factors could cause traditional steel to deteriorate quickly.

One of the key benefits of galvanized SHS is its strength and durability. They are able to withstand heavy loads and are resistant to corrosion, making them ideal for use in a wide range of applications. Galvanized SHS are often used in the construction of bridges, buildings, and other structures where strength and durability are important considerations. They are also used in the fabrication of various types of equipment, such as trailers, frames, and support structures.

In addition to their strength and durability, galvanized SHS are also known for their versatility. They can be easily cut, drilled, and welded to meet specific requirements, making them suitable for a wide range of applications. They are available in a variety of sizes and thicknesses to meet different design requirements.

In conclusion, galvanized square hollow sections are an essential component in the construction industry, providing strength, durability, and versatility. They are manufactured to meet strict quality standards and are able to withstand heavy loads and resist corrosion. Galvanized SHS is an excellent choice for outdoor applications where exposure to moisture and other environmental factors could cause traditional steel to deteriorate quickly.

FAQ:

Q1:What kind of work does your company do?

A1:Our company is a professional manufacturer. We mainly produce steel tubes/pipes/coils/round bars, etc.

Q2:Do you provide free samples?

A2:Yes, we can provide a free sample for testing.

Q3:How long is your delivery time?

A3: Generally it is 7-30 days and it is according to quantity.

Q4:How can we guarantee the quality?

A4:Always a pre-production sample before mass production; always final Inspection before shipment.