Thickness:0.5-2.5mm

Length:1-12m

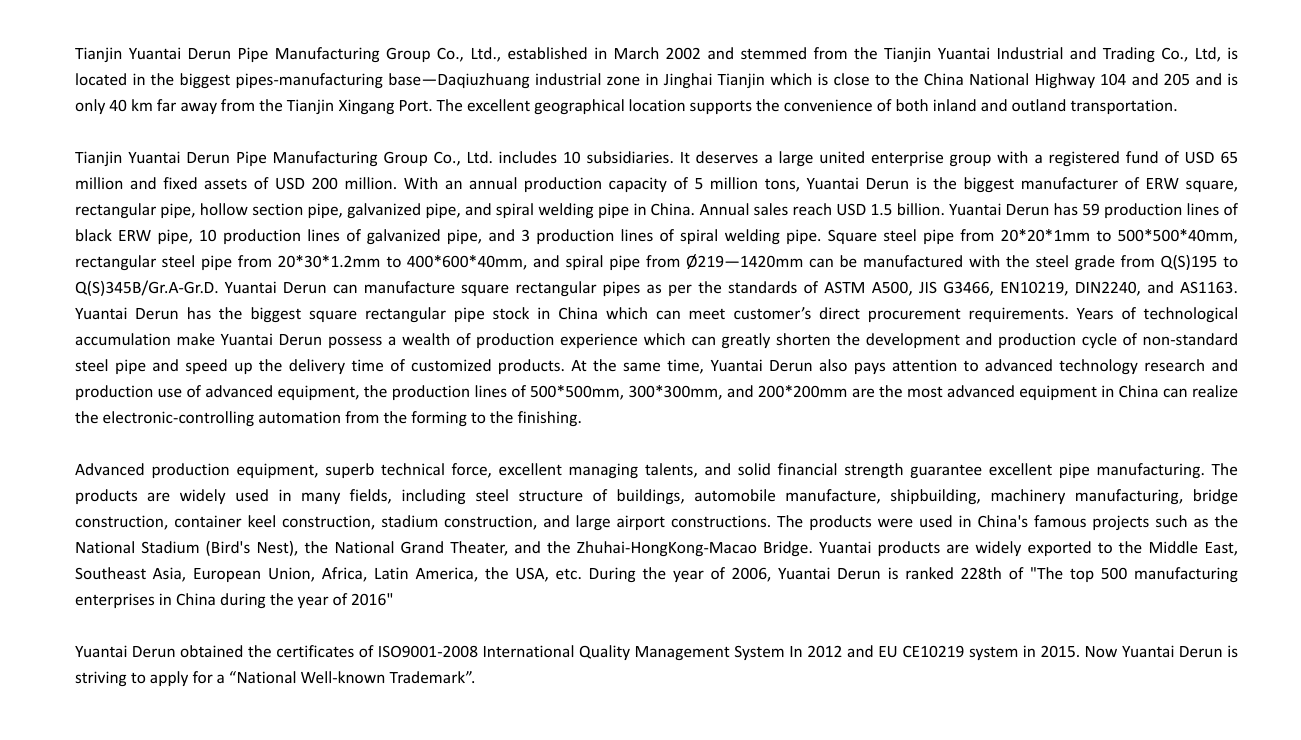

Product Specification

Specification | Outer Diameter | 13-266.6mm |

Thickness | 0.5-2.5mm | |

Length | 1-12m | |

Technique | Pre-galvanized or hot-dipped galvanized | |

Steel grades | Q195, Q235, Q355 | |

Application | galvanized warehouse shelf | |

Package | in the bundle, or wrapped with waterproof cloth as per the customers' requirement | |

Delivery Time | 10 days if stock is available; 30 days for new production | |

Loading Port | Xingang, Tianjin, China | |

MOQ | 25 tons | |

Others | 1. All the pipes are high-frequency welded. | |

2. Both inner and outer welded stabs can be removed. | ||

3. Special design available according to requirements. | ||

4. Pipe can be necked down and punched holes. | ||

5. Supplying BV or SGS Inspection if the client needs it. | ||

Can galvanized pipes be welded to make shelves?

1. wholesale galvanized pipe and its advantages in shelf construction

A galvanized pipe is a hot-dip galvanized steel pipe that can improve the corrosion resistance, wear resistance, and corrosion resistance of the steel pipe. When building racks, the advantages of galvanized pipe include its light weight, strength, ease of processing, and reliability.

2. Advantages of using galvanized pipe welding shelves

The main advantage of using galvanized pipe welded racking is the increased customization and adaptability you can achieve. Shelves of different sizes can be customized according to the needs of the project, and the layout of the shelves can be flexibly adjusted during the construction process.

3. Whether galvanized pipes can be used to weld shelves

Generally speaking, it is feasible to use galvanized pipe welding shelves, but two aspects need to be paid attention to. First of all, during the welding process, the coating on the pipe surface needs to be completely removed to avoid the welding quality being affected. Secondly, when welding, make sure that molten metal does not pool too much at the joint. This can be achieved by controlling the welding temperature and welding rate.

Our company: