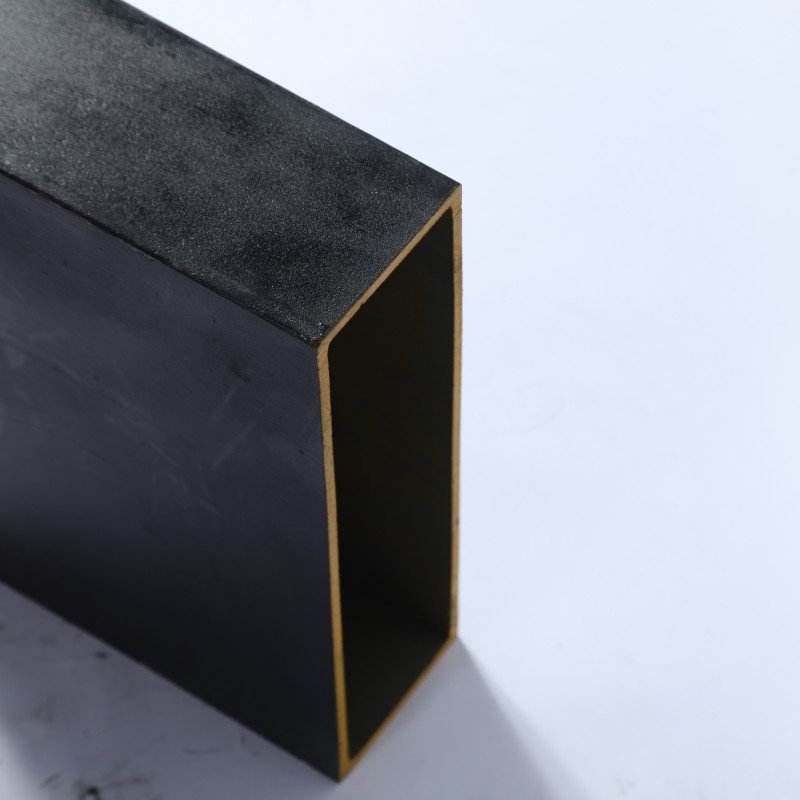

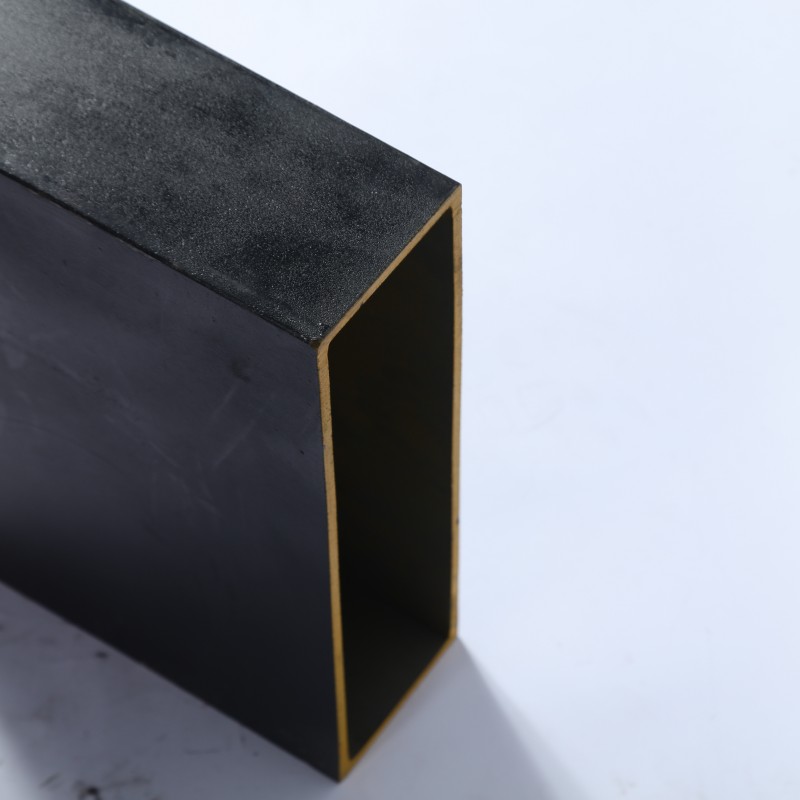

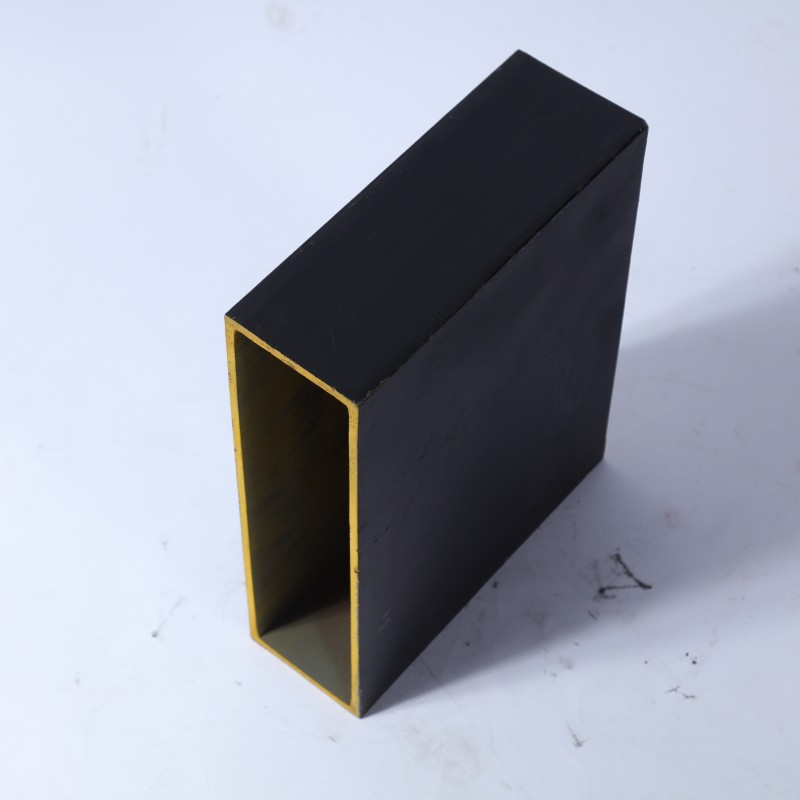

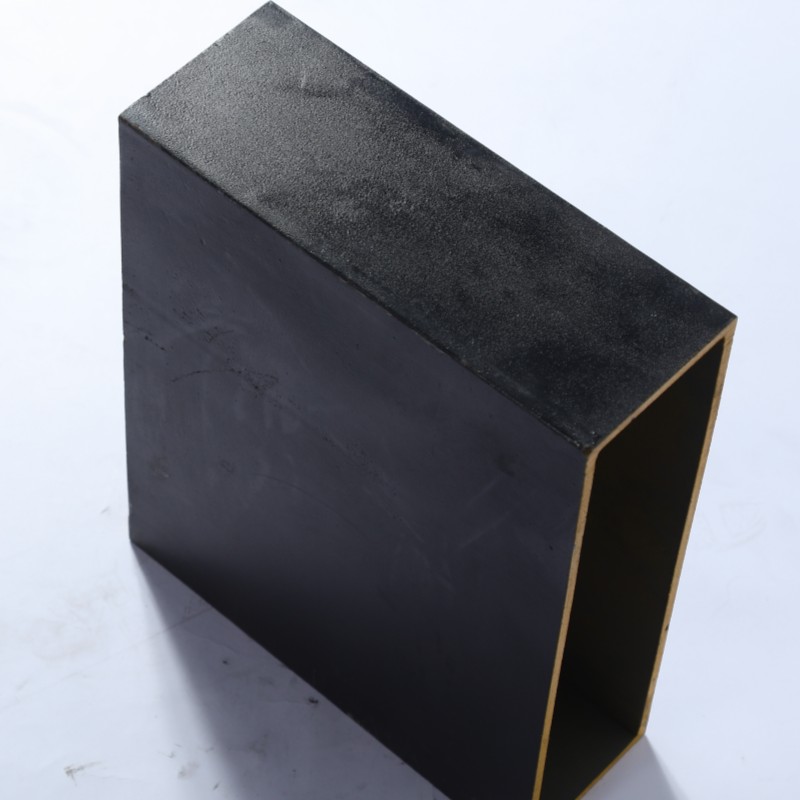

Size: 20*20-500*500mm or as the requirement,

large size steel tube above 500*500 can be produced.

Thickness: 1.3-40mm or as the requirement

Length: 5.8m/6m/12m or as the requirement

Product Specification

Size | 20*20-500*500mm or as the requirement, large size steel tube above 500*500 can be produced. |

Thickness | 1.3-40mm or as the requirement |

Length | 5.8m/6m/12m or as the requirement |

Steel grades | ASTM A500,ASTM A501,BS 1387,EN10219,EN10210,ASTM A53, JIS G3466, GB/T9711,GB/T3094,GB/T3091,GB/T6728 |

Application | Steel Frame Glass Curtain Wall Heavy steel structure Aerospace engineering High-speed rail Shipbuilding Seamless steel pipe for machinery Seamless steel pipes for automobiles and high-speed trains Seamless steel pipes for the chemical industry and boilers Seamless steel pipe for bridges |

Package | in the bundle, or wrapped with waterproof cloth as per the customers' requirement |

Delivery Time | 7-30 days |

Loading Port | Xingang, Tianjin, China |

MOQ | 10 tons |

1. All the pipes are high-frequency welded. 2. Both inner and outer welded stabs can be removed. 3. Pipe can be necked down and punched holes. 4. Supplying BV or SGS Inspection if the client needs it. | |

The production process of glass curtain wall square and rectangular tubes mainly includes glass cutting, edge processing, drilling, installation, and fixing.

1. Carry out glass cutting. The production of glass curtain wall square and rectangular tubes begins with glass cutting. According to actual needs, the raw glass plates are cut according to the designed size. Cutting glass requires the use of professional glass cutting tools, such as cutters or cutters. During the cutting process, it is necessary to ensure that the cutting lines are accurate and smooth to ensure that the produced glass square and rectangular tubes can achieve a perfect seam effect when spliced.

2. Perform edge processing. After cutting the glass, edge processing is required. Edge processing is mainly to eliminate the sharp edges produced after cutting glass and ensure that the edges are straight and smooth. Common edge processing methods include grinding, polishing, or using edge processing equipment. These treatments improve the strength and beauty of the glass.

3. Carry out drilling. According to the requirements of the design drawings, drill holes in the square and rectangular tubes of the glass curtain wall for fixing and installation in subsequent steps. During the drilling process, it needs to use a professional glass drill to ensure that the location and size of the hole are accurate, and to ensure that the glass will not break or crack during the drilling process.

4. Perform the installation. During the installation process, the pre-processed glass curtain wall square and rectangular tubes need to be spliced and assembled according to the design requirements, and fixed to the building frame. This step requires experienced installation workers to ensure that the splicing of each square and rectangular pipe is tight and regular and to avoid looseness or cracks.

5. Fix. Fix the installed glass curtain wall square and rectangular tubes to prevent them from shaking or loosening during use. The method of fixation depends on the specific situation. Usually, special metal clamps, glue, or bolts can be used for fixation.

The production process of glass curtain wall square and rectangular tubes requires multiple steps such as glass cutting, edge processing, drilling, installation, and fixing. Each step needs to be operated in strict accordance with the regulations and design requirements to ensure that the produced glass curtain wall square rectangular tubes have sufficient strength and beauty and can be effectively used for building curtain wall decoration.

Our factory: