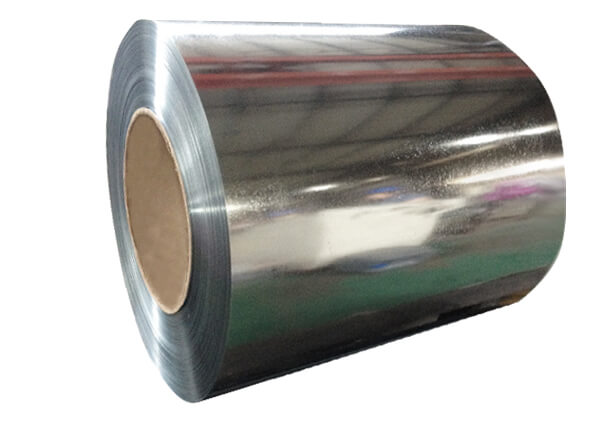

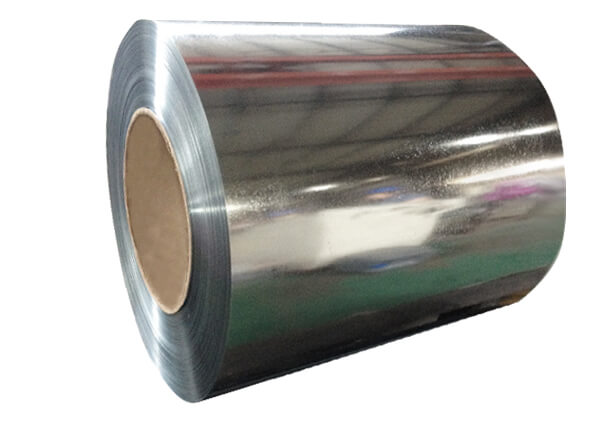

Home >> products >> Flat Steel Products >> Galvanized Coil

Width: 30-1500mm

Thickness: 0.12-4.0mm

Length: as per the customer's requirement

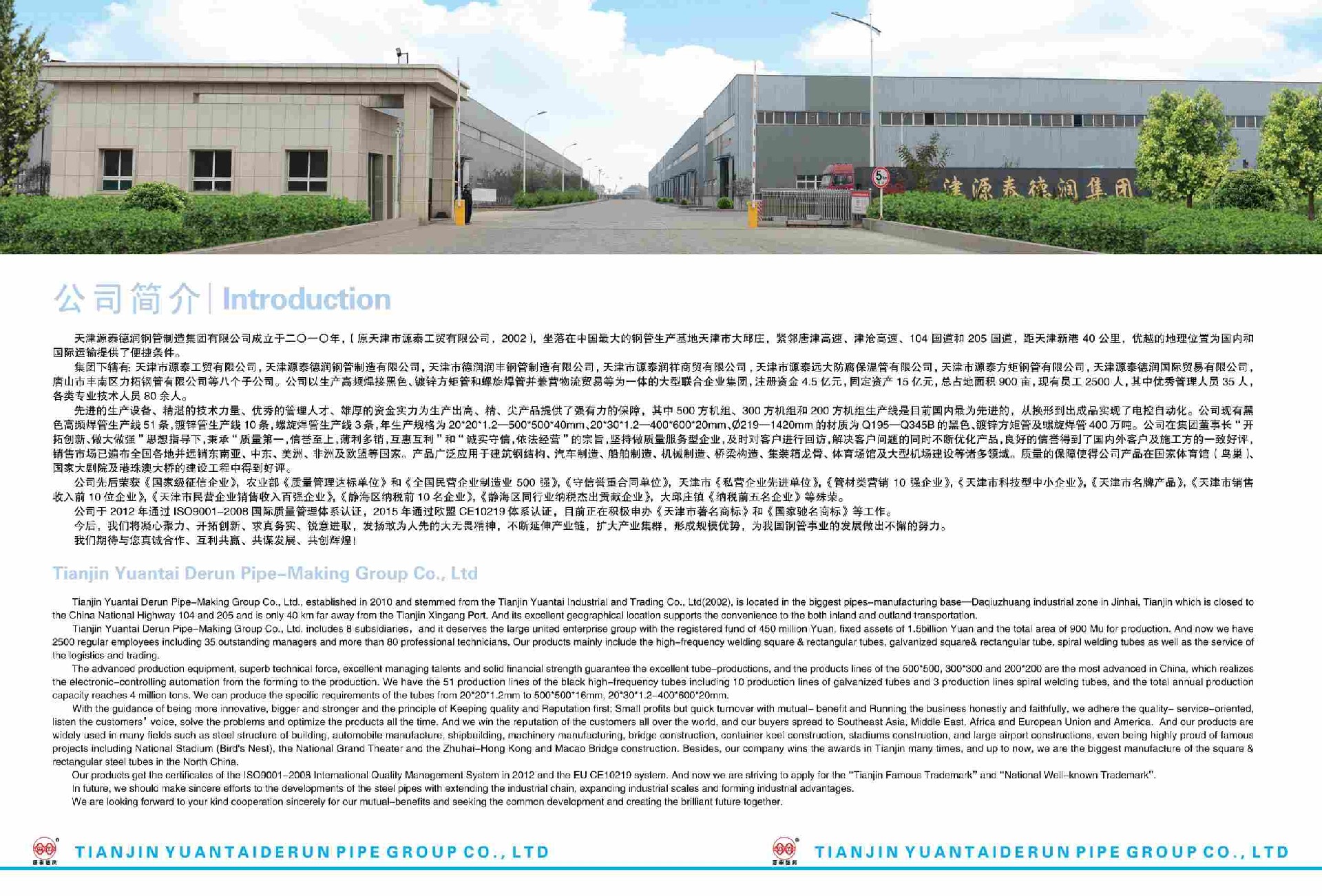

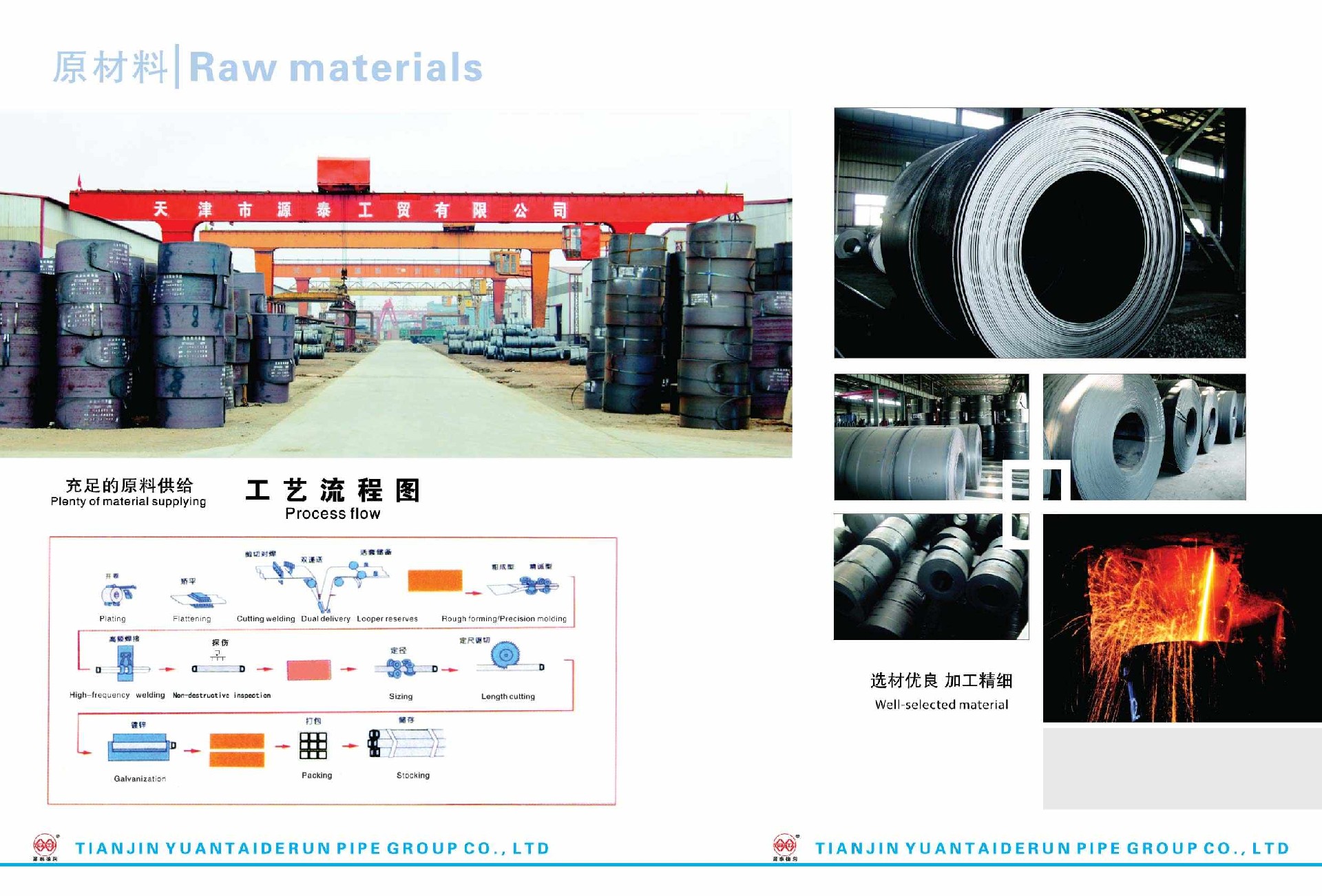

The galvanized coil is a thin steel sheet that has been dipped in molten zinc to apply a zinc layer to its surface. It is mostly produced using the continuous galvanizing process, which involves continually dipping the coiled steel plate in the galvanizing tank with the molten zinc to produce galvanized steel plate; an alloyed galvanized steel plate. This type of steel panel is also created by hot dip, but it is heated to roughly 500°C soon after leaving the tank to generate an alloy coating of zinc and iron. This galvanized coil is easily painted and weldable.