Steel grade: S350\S420\S450

Processing: Ordinary processing and custom processing are available

Other accessories or requirements can be ordered

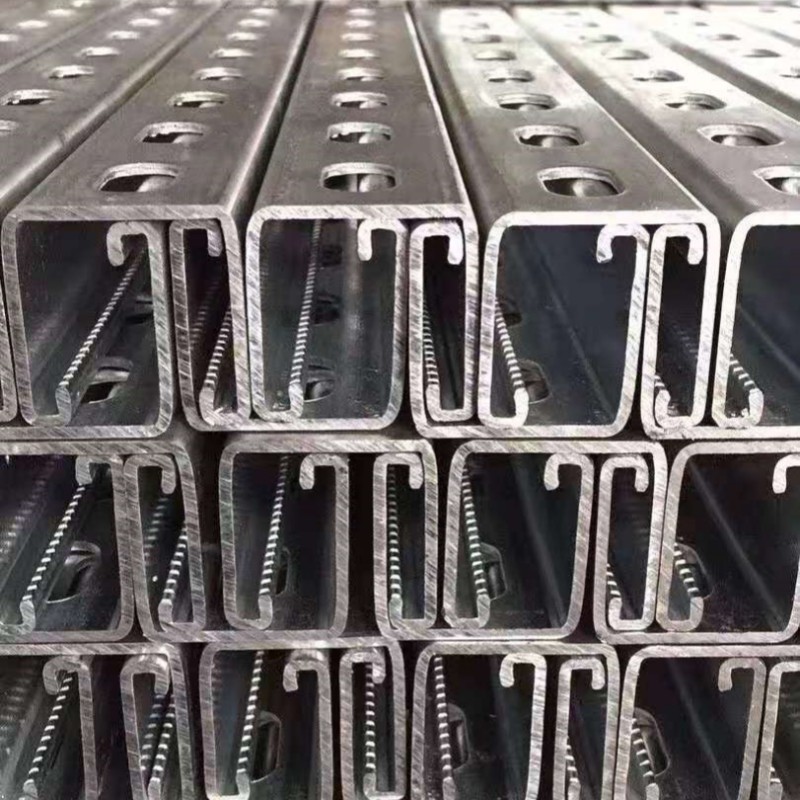

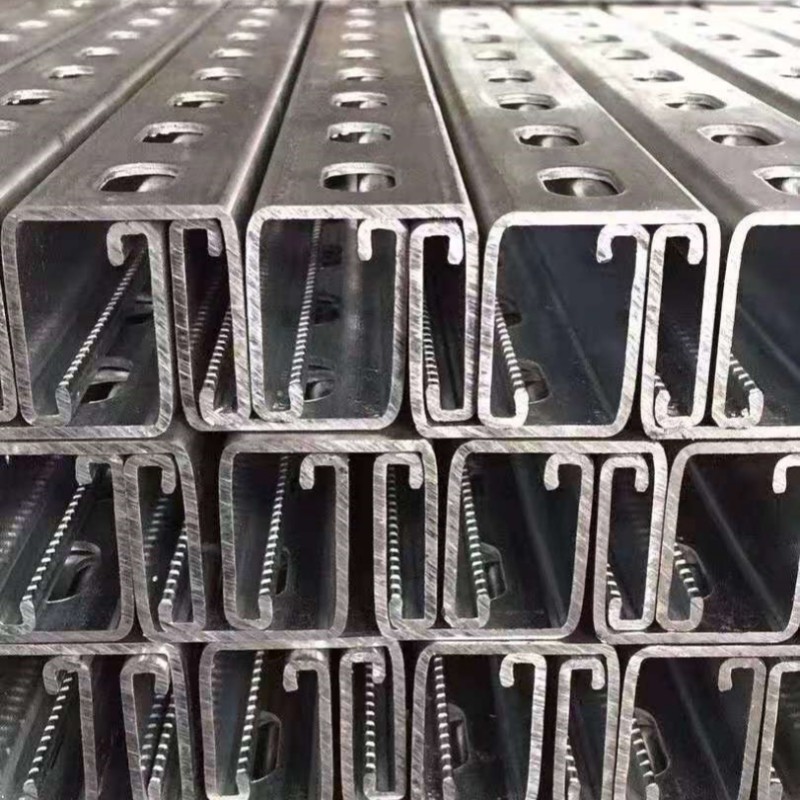

Product Details:

Item | Zinc Aluminum Magnesium Coated Steel photovoltaic bracket |

Surface Treatment | Galvanized zinc aluminum magnesium |

Steel grade | S350\S420\S450 |

Processing | Ordinary processing and custom processing are available |

Terms of payment | L/C, T/T |

Delivery | 7-30days |

Supplying BV or SGS Inspection if the client needs it. Other accessories or requirements can be ordered. | |

The introduction of zinc aluminum magnesium photovoltaic bracket:

Al, Mg, Si, and other alloying elements are added to the coating of super corrosion-resistant zinc-aluminum-magnesium steel plates, which greatly improves the corrosion inhibition effect of the coating. Compared with ordinary galvanized products, the coating has less adhesion but can achieve better corrosion resistance. It is 10 to 20 times that of hot-dip galvanized steel plate.

Self-repairing of zinc-aluminum-magnesium products means that in a humid corrosive environment on the cut surface, the coating material near the cut dissolves into the water film attached to the surface of the exposed metal and continuously migrates to the exposed cut position, forming a hydrogen oxide A dense protective film (white rust) composed of zinc, alkaline zinc chloride and magnesium hydroxide gradually covers the exposed cut metal, separating the external corrosive medium from the exposed metal matrix, thereby preventing further corrosion of the exposed cut. The whole process will take a long time.

The key component of long-life zinc, aluminum, and magnesium is the addition of Mg-Al-Zn, which has strong and reliable resistance to chlorine (edible salt/sweat stains/sea surface/night breeze/soil layer) and alkali corrosion resistance, ensuring 20-30 years Does not produce red rust.

This is a coating product with excellent comprehensive performance. It can be 10-20 times stronger than zinc plating at the same coating amount. It has excellent protection for the cut-off and has good welding performance. Mainly suitable for BIPV, offshore photovoltaic, desert photovoltaic, and other application scenarios.

Our company: