Home >> products >> Open Section >> Z Purlin

Wall thickness:1.5-4mm

Height:20-300mm

Product Specification

Size | 40-500mm |

Wall thickness | 1.5-4mm |

Height | 20-300mm |

Technique | Hot Rolled Steel |

Surface | Galvanized & Black or as your request |

Treatment | polish;painted;galvanized;punched |

Material Grade | JIS, ASTM, GB, EN, etc. |

Package | in bundle |

Delivery Time | 20-25 days for production |

Loading Port | Xingang, Tianjin, China |

MOQ | 3-5 tons |

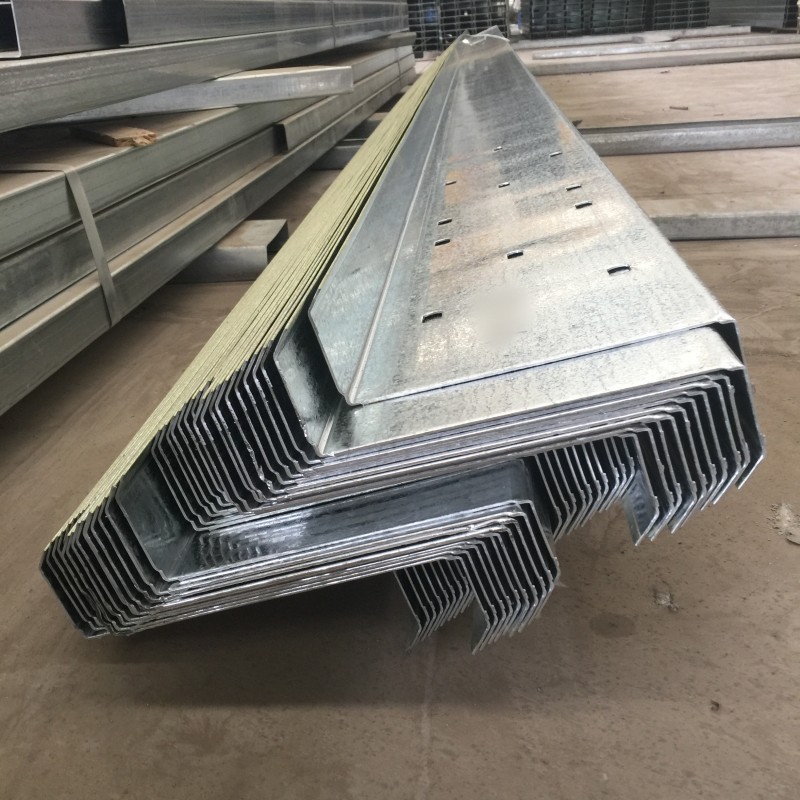

What is the difference between C purlin and Z purlin used in steel structure processing?

Just looking at the appearance, the angles of z purlins for sale and C purlins are different. Type C is 90 degrees, while type Z is less than 90 degrees, which is about 60-75 degrees. Therefore, when purlins are used on roofs with a certain slope, they must be combined. The angle of the purlin should be taken into account when stressing. If the slope is large, the Z-shape can be used to make full use of its bending resistance. If you want to make purlins into continuous components during steel structure processing, you should choose Z-shaped steel purlins instead of C-shaped steel purlins. This is because the overlap of Z-shaped steel purlins is more convenient.

From the perspective of bending resistance, when the roof slope is relatively small, the bending resistance section of purlin z is slightly larger than that of C-shaped purlins, but the difference is not particularly large. When the slope of the roof increases, the Z purlins have a higher bending resistance in the vertical direction. The utilization rate of the bending section is increased, so Z-shaped steel purlins are suitable for roofs with large slopes.

Then from the cross-section point of view, the mechanical properties of the strong and weak axes of C-shaped steel and Z-shaped steel are quite different, and the connection with the steel frame is mostly bolted. When calculating, it needs to be considered as simply supported, while the Z-shaped section can be reliably connected by The connection is realized by overlapping, which can be calculated as a continuous beam. Therefore, from the perspective of stress state, calculation results, and structure, the Z-type seems to be more reasonable. Therefore, in addition to dealing with door and window openings and other special processing needs, Z-shaped steel is still the first choice. During the entire steel structure processing process, C-shaped steel can be used for wall purlins and roof purlins with a small shelving slope. Z-shaped steel purlins are suitable for roof purlins with a large shelving slope so that the roof load force can be reduced through the Z-shaped purlin section.

Whether it is C-shaped steel or Z-shaped steel, it can be fully utilized as long as it is placed in the right position. For the processing of the entire steel structure component, both of them are raw materials that need to be used in steel structure engineering. As long as the raw materials are qualified, Process components that meet standards.

Our company: