The quality of hot-dip galvanized sheet depends largely on the zinc content (calculated per square meter) in the hot-dip galvanized sheet. The higher the content of the hot-dip galvanized sheet, the better the corrosion resistance of the hot-dip n galvanized sheet; in addition to its content, we also need to consider its performance when choosing a hot-dip galvanized sheet. The performance of hot-dip galvanized sheet can be judged by the bending test and tensile test. The zinc layer of a qualified hot-dip galvanized sheet will not fall off after being bent at 180 degrees; similarly, a qualified galvanized sheet will not break after a tensile test.

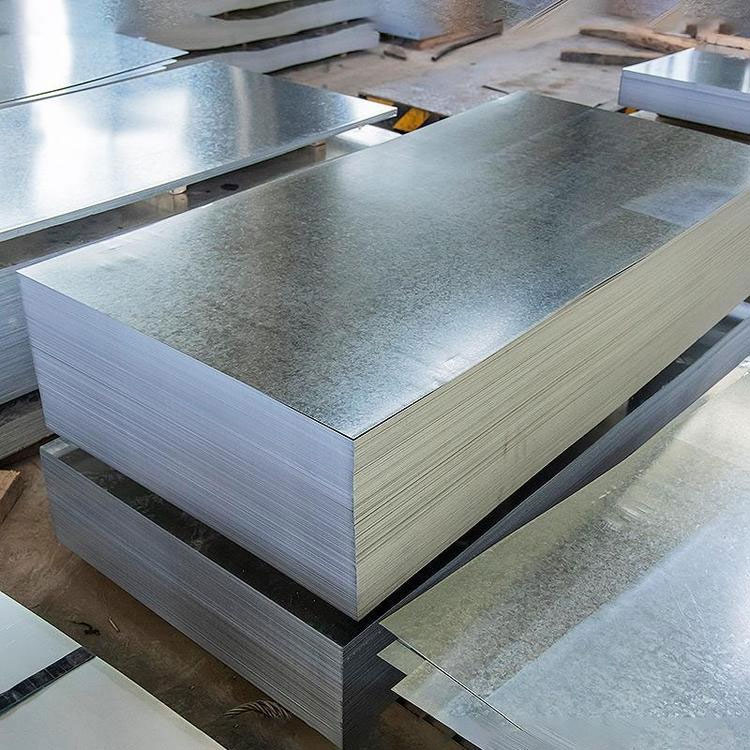

Generally speaking, the thickness specifications of steel on the market are the same. The thickness specifications of galvanized steel sheets should be selected according to the user's construction conditions, and should not be selected blindly. Coating a layer of zinc on the steel plate is like a protective film with anti-corrosion ability, which has considerable advantages in durability and can prolong the service life. The well-received galvanized steel sheets generally have brand support, and of course, their own quality is also very good. Although galvanized steel is relatively thin, its quality is self-evident. The thickness specifications of galvanized steel sheets on the market are mostly limited. The galvanized steel sheet made by special process can be used for a long time. There is a zinc layer on the surface of the steel plate to prevent rust.

We should look at the basic material because the quality of the basic metal material of the galvanized sheet is closely related to the quality and durability of the finished galvanized sheet, so we must pay attention to this detail when choosing a product. Galvanized sheet factory, galvanized sheet, hot-dip galvanized sheet, galvanized coil, galvanized iron sheet, hot-dip galvanized sheet price, white iron sheet and the provision of high-quality materials are the basic conditions for industrial production to have quality assurance. Pay attention to price comparisons. OK, maybe expensive. However, if the product is cheap, it must not be credible. Hot galvanizing is basically due to a chemical reaction while cold galvanizing is due to a physical reaction. Cold galvanizing is basically just a layer of zinc on the surface, so the zinc layer is particularly easy to fall off. It is recommended to use hot dip galvanizing during construction. For galvanized steel sheets, only by fully understanding its various aspects can we make better use of it, so as to give full play to its role and serve us better. When buying galvanized steel sheets, don't be greedy for meager profits, but choose galvanized steel sheets with high cost performance.

When choosing a hot-dip galvanized sheet, you can also see how the overall situation is? Better selection of product offers on the market and services of manufacturers. After all, the choice of substrate is also important now. For the most part, it can be used with better performance. The cost includes not only aluminum but also zinc and a small amount of silicon. It can be seen that when we pay attention to the product itself, we can also see its characteristics of the product itself. The anti-corrosion performance of galvanized products is very good, and the evaluation in the market is also very high. It is recommended that you choose according to your actual needs, or look at the approval of the entire market so that you can use it more confidently.