When using galvanized sheet products, users should choose the appropriate surface treatment method according to their processing technology, coating method, coating equipment, etc. The storage time of this product is thus shortened as much as possible. Choosing the right surface treatment can reduce the tendency to white rust during transportation and storage, improve the adhesion of the paint layer, and protect the coating. Chromium-free passivation is not recommended for phosphating and coating after treatment.

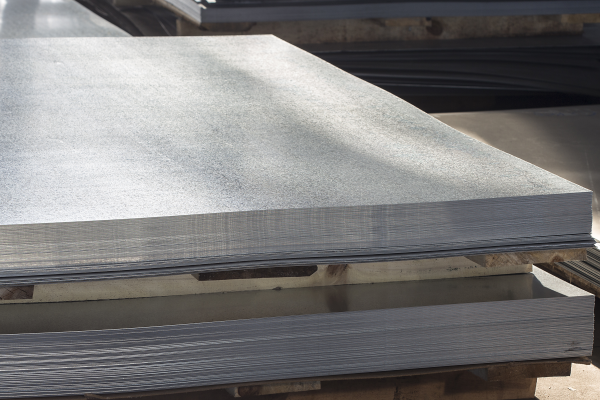

Due to the different treatment methods throughout the galvanizing process, the surface state of galvanized products may also present various types, such as ordinary spangle and flat spangle. Generally speaking, as long as it is processed and manufactured according to the regulations, the performance of the product will be better and the condition will be good. According to the overall appearance requirements, galvanized products shall not be used in actual use, such as excessive defects such as holes or scratches. These do not meet the requirements. Generally speaking, it will be strictly explained during the processing and manufacturing process. The surface technology is finer and the product is safer to use.

Generally speaking, the main surface of hot-dip galvanized sheet products should be visually smooth, free of nodules, roughness and burrs (if these zinc thorns will cause damage), peeling, missing plating and residual flux slag. Parts that may affect the use or corrosion resistance of hot-dip galvanized steel gratings must not contain zinc nodules and zinc dust. As long as the steel grating coating thickness is greater than the specified value, the surface of the steel grating plated parts is allowed to have dark gray or light gray uneven areas. White rust (white or gray corrosion products mainly based on alkaline zinc oxide) is allowed to appear on the surface of galvanized steel gratings stored under humid conditions. "

Improve the surface color of galvanized sheet. For small and zinc-free products, galvanized sheet can obtain a more uniform surface gloss through surface treatment. Using large spangle products as the base material of color paint can make the spangles formed by large spangle crystals smooth and uniform, with different luster, blur the spangles, and help cover the spangles when painting.