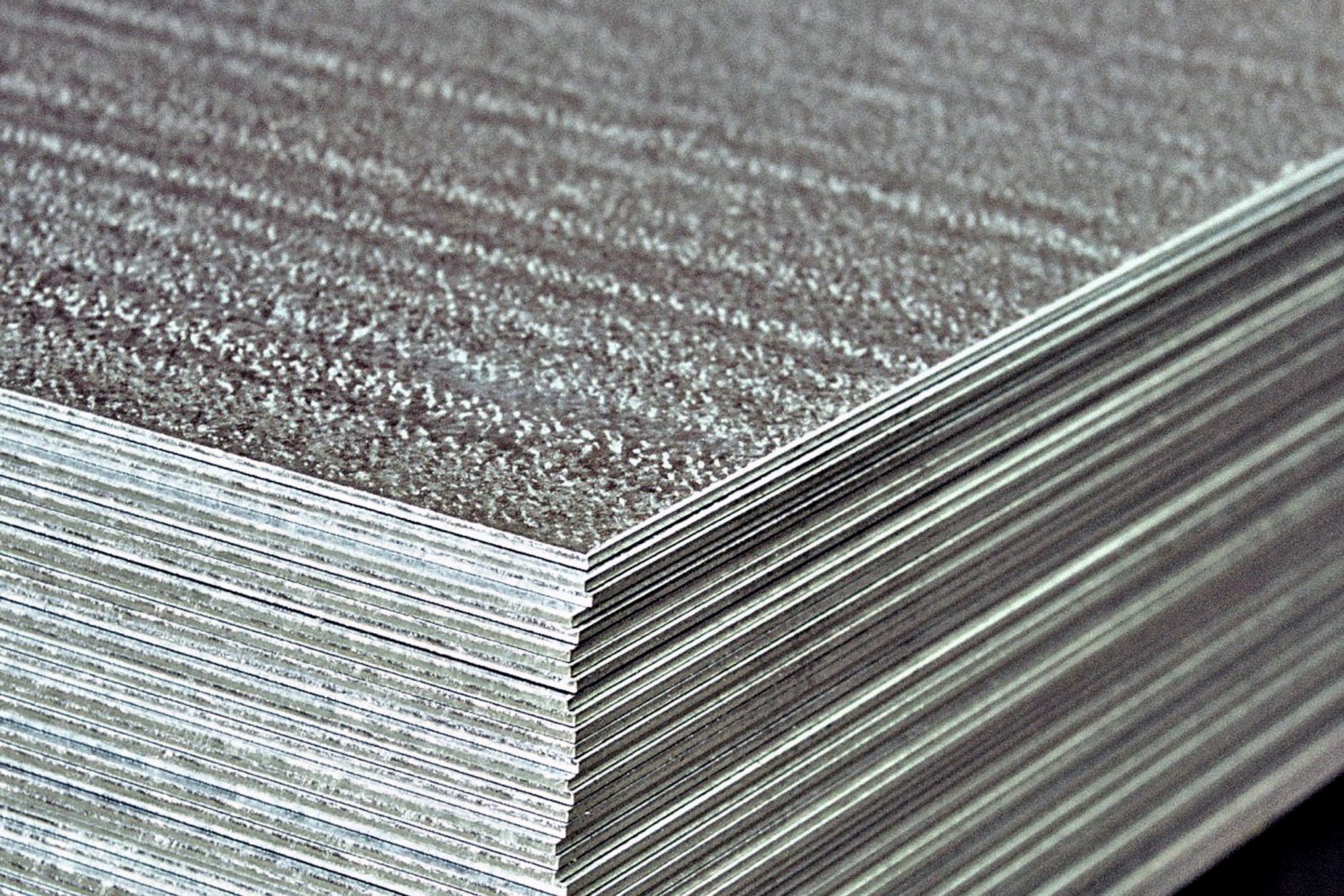

In industrial production, high-quality materials must be selected to achieve the goal of reliable product quality. Galvanized sheet is a high-quality raw material for special industrial production, which is very suitable for many household products. Therefore, the selection of high-quality materials has become a necessary condition for improving production efficiency and product quality. For production enterprises, galvanized sheet materials should be selected and compared with professional standards. Strict professional standards become an important condition for the selection of high-quality materials.

Galvanized sheet generally includes hot-dip galvanized sheet, alloy galvanized sheet, electro-galvanized steel sheets, single-sided galvanized sheet, and double-sided galvanized sheet. These typical galvanized sheets are also used in different places due to different production and processing methods. In contrast, galvanized sheet is mainly used in industries such as construction, light industry, automobiles, agriculture, animal husbandry and fishery. Among them, it is mainly used in the manufacture of anti-corrosion industrial products and roofs of civil buildings. In the automotive industry, galvanized sheet is mostly used in the manufacture of corrosion-resistant parts for automobiles. In the light industry, it is widely used in kitchen appliances, home appliances, houses, etc. Because of its wide range of use and good corrosion resistance, it is welcomed by the market and recognized by consumers.

Other steel manufacturing uses galvanized sheet: colored thick steel sheets use hot-dip galvanized sheet, hot-dip aluminum-zinc sheet, and electro-galvanized sheet, etc. The types of galvanized sheet prepared on the surface include hot-dip galvanized sheet strips, Galvanized sheet, galvanized sheet is constrained to form, including connecting hooks, when connecting steel mesh and columns, it can be strong without any parts. Galvanizing is a key method for steel corrosion protection. Zinc can not only produce a high-density protective layer thickness on the steel surface, but also has the practical effect of cathodic protection for pipelines. When the galvanized layer is damaged, according to the cathodic protection effect of the pipeline, the corrosion of the iron butt welding can still be avoided.

As an important industrial material, galvanized sheet needs to select excellent materials and galvanizing process to ensure that its application effect has better functions. After the design of the galvanizing process, it is necessary to ensure that the product is of good quality, which requires high requirements for the production enterprise. When choosing a good galvanized sheet, we should pay full attention to the brand and comprehensive quality. From the perspective of the demand of production enterprises, there is a great demand for high-quality galvanized sheets.