1. Different definitions: Welded steel pipe refers to a steel pipe with seams on the surface that is welded after bending and deforming a steel strip or steel plate into a shape such as a circle or a square. Galvanized welded pipe is welded steel pipe coated with galvanized steel.

2. Different classifications: Welded steel pipes can be divided into arc welded pipes, high-frequency or low-frequency resistance welded pipes, gas welded pipes, furnace welded pipes, Bondi pipes, etc. according to different welding methods. According to the shape of the weld, it can be divided into straight seam welded pipe and spiral welded pipe. Galvanized pipes are divided into cold-galvanized pipes and hot-galvanized pipes.

3. Different uses: welded steel pipes can be used in oil drilling and machinery manufacturing, and can also be used as water and gas pipes, etc. Large-diameter internal longitudinal welded pipes can be used in high-pressure oil and gas transportation. Galvanized welded steel pipes for low-pressure fluid transportation are mainly used for conveying water, gas, air, oil, heating water or steam, and other general low-pressure fluids and pipes for other purposes. Spiral welded pipes are used for oil and gas transportation, pipe piles, bridge piers, etc. Galvanized welded pipes are generally used for the transportation of low-pressure fluids.

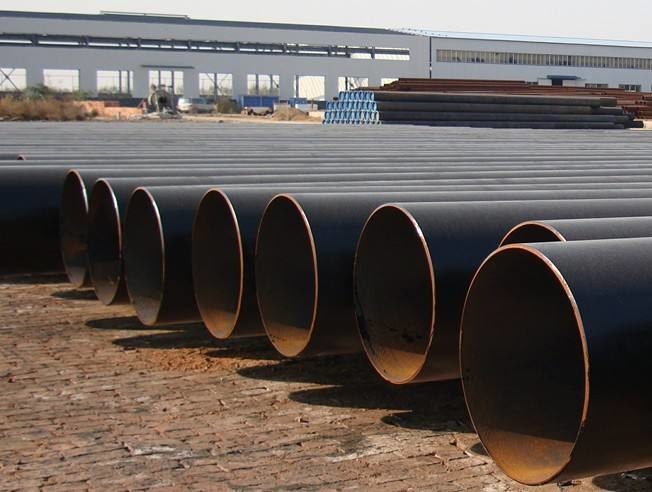

Welded steel pipe, also known as welded pipe, is a steel pipe made of steel plate or strip steel after bending and welding, generally with a length of 6 meters. Welded steel pipe has a simple production process, high production efficiency, many varieties and specifications, and less investment in equipment, but its general strength is lower than that of seamless steel pipe. It is divided into general welded pipe, galvanized welded pipe, oxygen-blown welded pipe, wire casing, metric welded pipe, idler pipe, deep well pump pipe, car pipe, transformer pipe, electric welded thin-walled pipe, electric welded special-shaped pipe, scaffold pipe, and spiral welded pipe.

Ordinary welded pipe: Ordinary welded pipe is used to transport low-pressure fluid. Made of Q195A, Q215A, Q235A steel. It can also be made of other mild steels that are easy to weld. Steel pipes are subject to water pressure, bending, flattening, and other tests, and have certain requirements for surface quality. Generally, the delivery length is 4-10m, and fixed-length (or double-length) delivery is often required.

The standard of the welded pipe indicates the nominal diameter (millimeters or inches). The nominal diameter is different from the actual one. The welded pipe has two types of regular wall thickness: ordinary steel pipe and thickened steel pipe. Galvanized pipe: In order to improve the corrosion resistance of steel pipes, general steel pipes (black pipes) are galvanized.

There are two types of galvanized pipes: hot-dip galvanized and electric steel zinc. The hot-dip galvanized layer is thick, and the cost of electric galvanized is low. Oxygen-blowing welded pipe: used for steel-making oxygen-blowing pipe, generally small-diameter welded steel pipe, the standard is from 3/8 inch to 2 inches. Made of 08, 10, 15, 20, or Q195-Q235 steel strip. In order to prevent corrosion, some are aluminized. Wire casing: that is, ordinary carbon steel electric welded steel pipe, used in concrete and various structural power distribution projects, the commonly used nominal diameter is from 13-76mm. The wall of the wire casing is thin, and most of them are used after coating or galvanizing. A cold bending test is required.