Selecting the appropriate square steel pipe for your project involves considering various factors to ensure the pipe meets the required specifications and performs its intended function effectively. Here is a guide to help you make the right choice:

Square steel pipes are available in a variety of sizes, each defined by its dimensions. It's essential to refer to a square steel pipe size chart to understand the different dimensions available. This will help you select the right size for your specific application, whether it's construction, fencing, furniture manufacturing, or the automotive industry.

Determine the weight and load the pipe will bear to ensure the selected size can handle the intended application. This is crucial for applications where the pipe will support heavy structures or machinery.

Measure the available space where the pipe will be installed to ensure the chosen size fits appropriately. This is particularly important in confined areas or where precise measurements are required for the project's design.

Consult project plans and specifications to identify the required square steel pipe dimensions. This will help ensure that the pipe you select aligns with the overall project requirements and standards.

The material of the square steel pipe is defined by its type, joint efficiency, wall thickness, and manufacturing standard. Common material names include carbon steel, stainless steel, and chrome-moly steel. Each material type has specific grades and standards, such as ASTM A106 for carbon steel or ASTM A312 for stainless steel.

Consider the standard for wall thickness, which may be expressed as different schedules or plate thickness. The minimum wall thickness should be able to withstand its own weight with minimum deflection, calculated for the design temperature and pressure.

Determine the type of end connections required for your piping system. For socket weld systems, the pipe should be square cut, while butt-welding ends should comply with ASME B16.25 standards.

Specify the required lengths of the pipe and whether galvanizing is necessary. Galvanizing, when required, should be applied in accordance with ASTM A53.

There may be special requirements for the base material, fabrication, or inspection. These should be clearly indicated in the purchase description, including the need for mill test and chemical analysis reports for alloy pipes.

Different industries have specific needs. For example, the oil and gas industry often requires pipes that can handle high pressure and corrosive environments, making seamless pipes a preferred choice. In contrast, the construction industry may opt for welded pipes due to their cost-effectiveness.

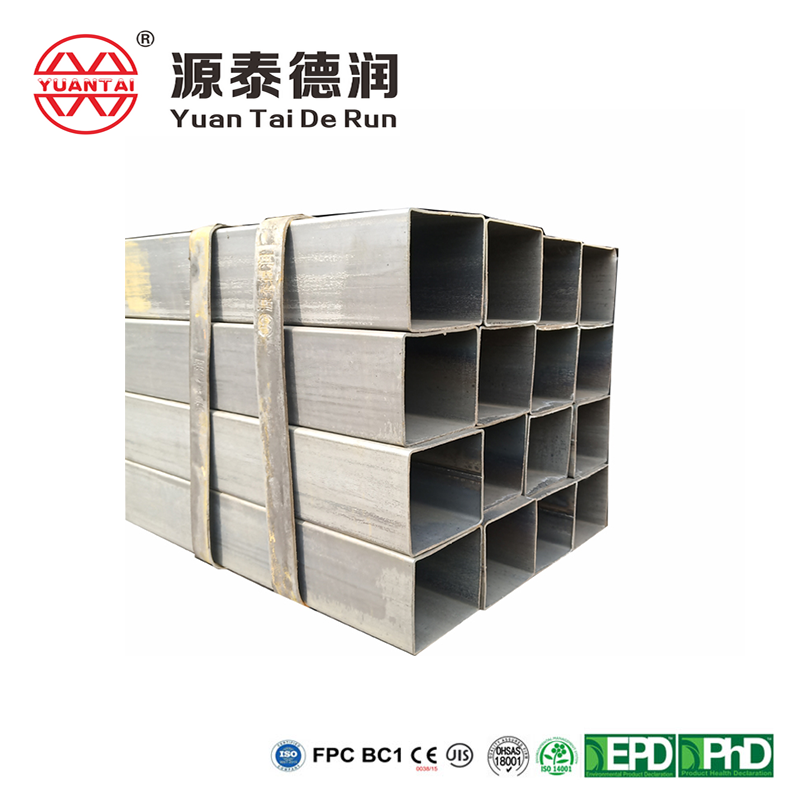

By considering these factors, you can select the square steel pipe that best fits your project's needs, ensuring both structural integrity and longevity. Remember to consult with reputable suppliers -YUANTAI DERUN to acquire square steel pipes that meet your specific requirements.

TIANJIN YUANTAI DERUN PIPE MANUFACTURING GROUP CO., LTD