Yield strength of steel is the yield limit of a metal material when it yields, that is, the stress that resists a small amount of plastic deformation. For metal materials without obvious yield phenomenon, it is stipulated that the stress value that produces 0.2% residual deformation is used as its yield limit, which is called conditional yield limit or yield strength of steel.

External forces greater than the yield strength of steel will cause the part to fail permanently and cannot be recovered. For example, the yield limit of low carbon steel is 207MPa. When the external force is greater than this limit, the part will be permanently deformed. If it is smaller than this, the part will return to its original state.

Yield strength of steel: It is the yield limit of a metal material when it yields, that is, the stress that resists a small amount of plastic deformation. For metal materials without obvious yield, it is stipulated that the stress value that produces 0.2% residual deformation is its yield limit, which is called conditional yield limit or yield strength. External force greater than this limit will cause the part to fail permanently and cannot be recovered. For example, the yield limit of low carbon steel is 207MPa. When the external force is greater than this limit, the part will be permanently deformed. If it is smaller than this, the part will return to its original state.

(1) For materials with obvious yield phenomenon, the yield strength of steel is the stress at the yield point (yield value);

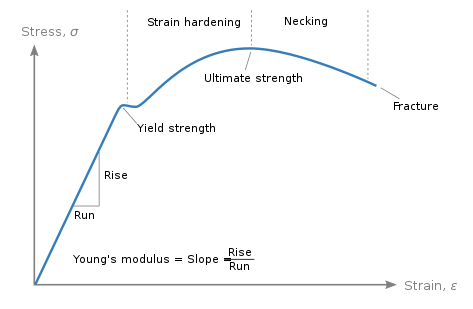

(2) For materials with insignificant yielding phenomena, the stress at which the limit deviation of the linear relationship of stress-strain reaches a specified value (usually 0.2% of the original gauge length). It is usually used as an evaluation index for the mechanical and mechanical properties of solid materials, and is the actual use limit of the material. Because the necking occurs after the stress exceeds the yield limit of the material, the strain increases, and the material is damaged and cannot be used normally.

When the stress exceeds the elastic limit and enters the yield stage, the deformation increases rapidly. At this time, in addition to elastic deformation, partial plastic deformation also occurs. When the stress reaches point B, the plastic strain increases sharply, and the stress and strain fluctuate slightly. This phenomenon is called yielding. The maximum and minimum stresses at this stage are called the upper and lower yield points, respectively. Since the value of the lower yield point is relatively stable, it is used as an indicator of material resistance, which is called yield point or yield strength of steel (ReL or Rp0.2).

Some steels (such as high carbon steels) have no obvious yield phenomenon, and the stress when a small amount of plastic deformation (0.2%) occurs is usually used as the yield strength of steel, which is called the conditional yield strength of steel.

First, explain the deformation of the material. The deformation of the material is divided into elastic deformation (the original shape can be restored after the external force is removed) and plastic deformation (the original shape cannot be restored after the external force is removed, and the shape changes, elongates or shortens).

Construction steel uses yield strength of steel as the basis for design stress.