In the process flow of square tube steel, welding has always been a challenging step. When welding, in particular, you need to pay attention! Avoid getting wet while welding outside or in the tuyere, as this increases the risk of cracks. When welding high-carbon steel or alloy steel, it is important to use heating and heat preservation techniques according to the composition and properties of the raw materials. steps to put welding into practice.

Cracks can also be brought on by improper welding sequences. A dead knot of welding shrinkage force will form when the welding sequence is improper, preventing the weld from shrinking naturally. This leads to high shrinkage stress and weld cracks. The chemical makeup, crystal structure, smelting process, etc. of the square tube steel's raw materials are all factors that can contribute to welding cracks. For instance, the harder and more easily produced steel is during welding, the higher its carbon or alloy content. When the surrounding environment is cold during the welding process or there are excessively favorable conditions for heat dissipation, such as a tuyere, the heat dissipation is too rapid, which also results in cracks.

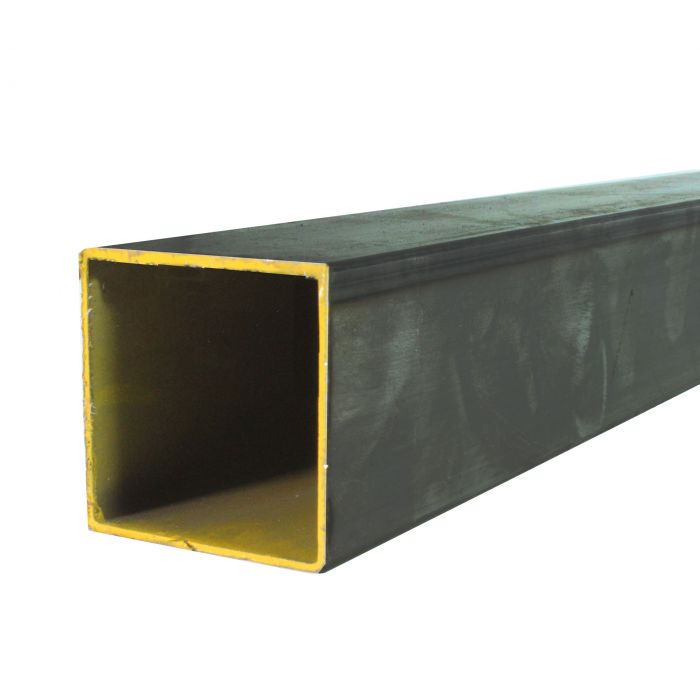

The square tube steel was welded using a welding rod that contains carbon, phosphorus, and sulfur; these elements are hazardous, and the weld is prone to cracking. Phosphorus levels must be kept to or below 0.0035. The majority of the current issues with square tube steel relate to the welding process and welding temperature. Low temperature and excessively quick cooling are both present during the welding process. I will demonstrate my understanding of the welding process for rectangular tubes, whether it be square tube steel that is first rounded and then squared, or a straight-out rectangular tube formed at one time. Both during the forming process and during the high-temperature season, the square tube steel will experience internal stress. Although the presence of stress won't be too problematic, it is more noticeable during the colder months of the year when temperatures are low. For instance, welding and loading and unloading both have the potential to cause cracking. The best course of action is to create quality In order to heat treat the square tube steel, which entails the heating and heat preservation procedures mentioned above, the rectangular tube is first sampled and tested to determine its mechanical properties (yield, tensile strength, etc.). The test results are then revealed. The square tube steel is placed into the trolley furnace, the temperature is changed in accordance with the recommended heating system, and the heating-constant temperature-insulation-cooling process is completed in the furnace. After heat treatment, the square tube steel itself can be removed. Internal stress significantly lessens the likelihood of cracking.

Don't rush to weld when the temperature is very low; doing so will significantly reduce cracks. Instead, warm the area to be welded with a flame or other method before welding. If you pour boiling water into a cold glass in the dead of winter, the glass might shatter because of the extreme temperature difference. For instance, if you fill a glass with warm water to raise its temperature, then fill a cup with boiling water, the likelihood of cracking is significantly reduced.