1. What are the connection methods of galvanized steel tube?

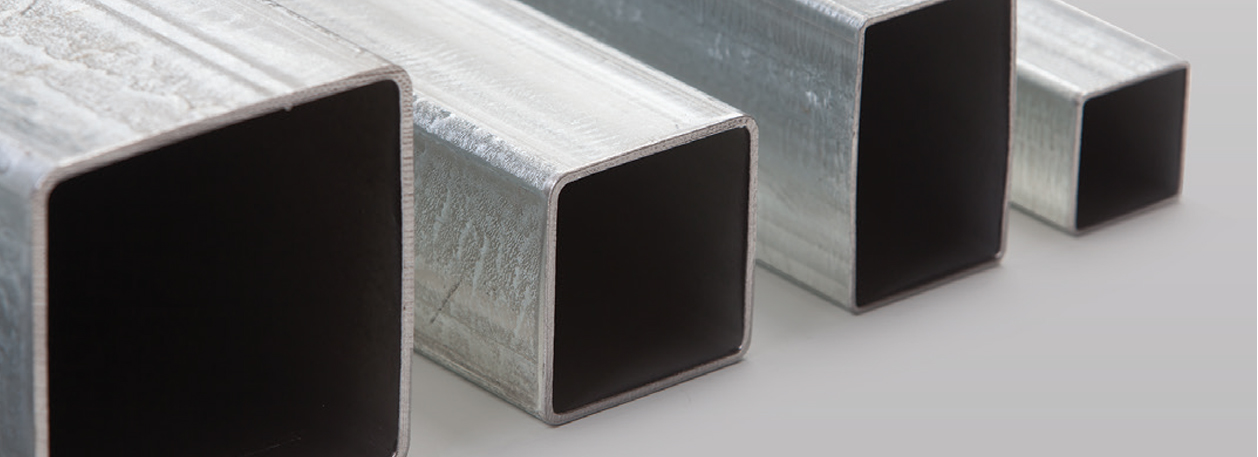

When using galvanized square tube, usually not only one galvanized square tube is used, and sometimes it is necessary to connect two or several galvanized square tube for use, which requires the correct connection method, then the galvanized square tube connection method How many are there?

1. Welding connection

It is more common to connect two galvanized square tube by welding, which is time-consuming, but the overall quality is relatively good, and it is not easy to leak after welding.

2. Clamp groove connection

Clamp groove connection is a popular connection method, and the construction is convenient. It is only necessary to machine two galvanized square tube with grooves and then connect them with clamps. However, this connection method requires higher quality of clamps. .

3. Flange connection

This method is to fix two galvanized square tube on one flange respectively and then fix the two flanges. The flange connection is generally used at the connecting valve. In addition, when the DN is greater than 100 mm, the galvanized Zinc steel pipes can be connected with welded flanges.

2. What problems should be paid attention to when connecting galvanized square tube?

There are many problems to pay attention to when connecting galvanized square tube, such as:

1. Select the appropriate connection method according to the design specification requirements and the size of the galvanized square tube fittings. For example, when the DN is not greater than 100 mm, it can be connected with a clamp groove.

2. Before connecting the galvanized square tube, screw the galvanized square tube by hand to check its tightness, and keep enough margin to tighten the pipe fittings.

3. After the galvanized square tube is connected, a water pressure test should be carried out to check whether there will be leakage at each connection. If there is, a mark should be made, and the repair will be completed.

4. When welding galvanized square tube to connect, it is recommended to cut off a small section of the pipe head before processing, so as to avoid problems such as poor butt joints between the two pipe ports after butt joints.