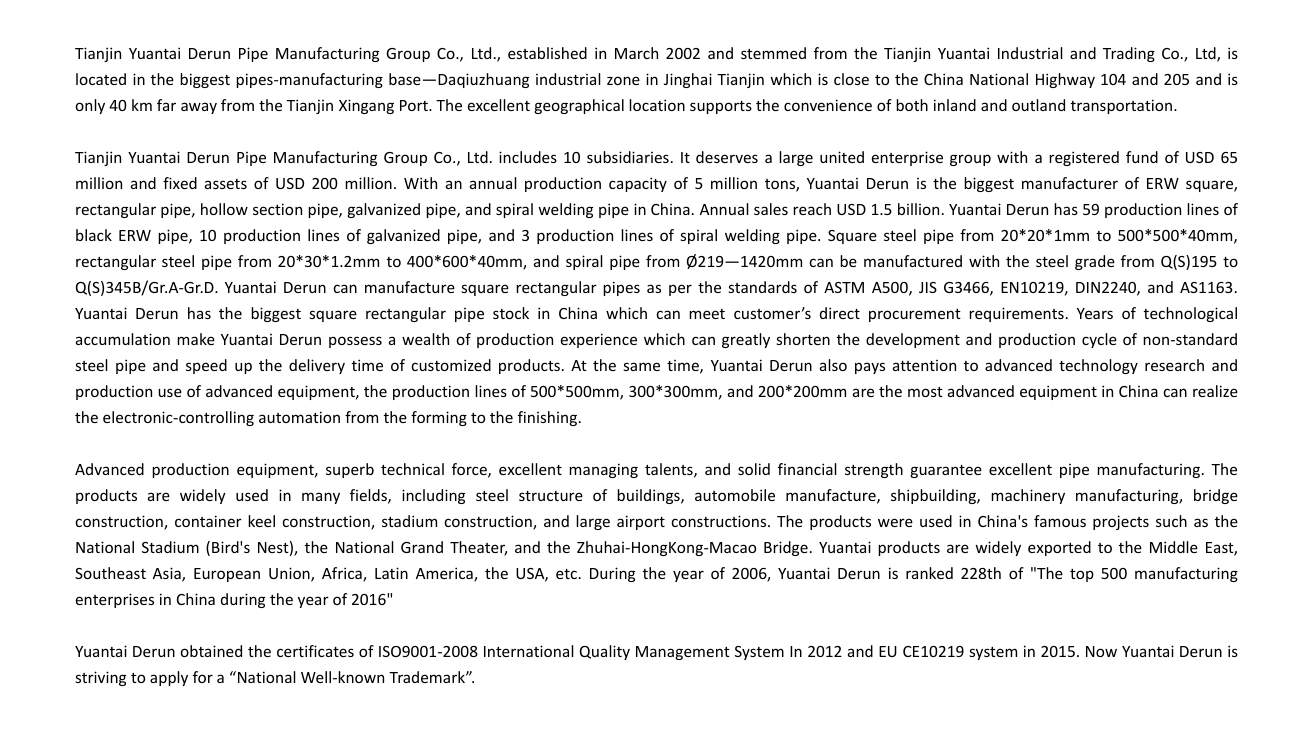

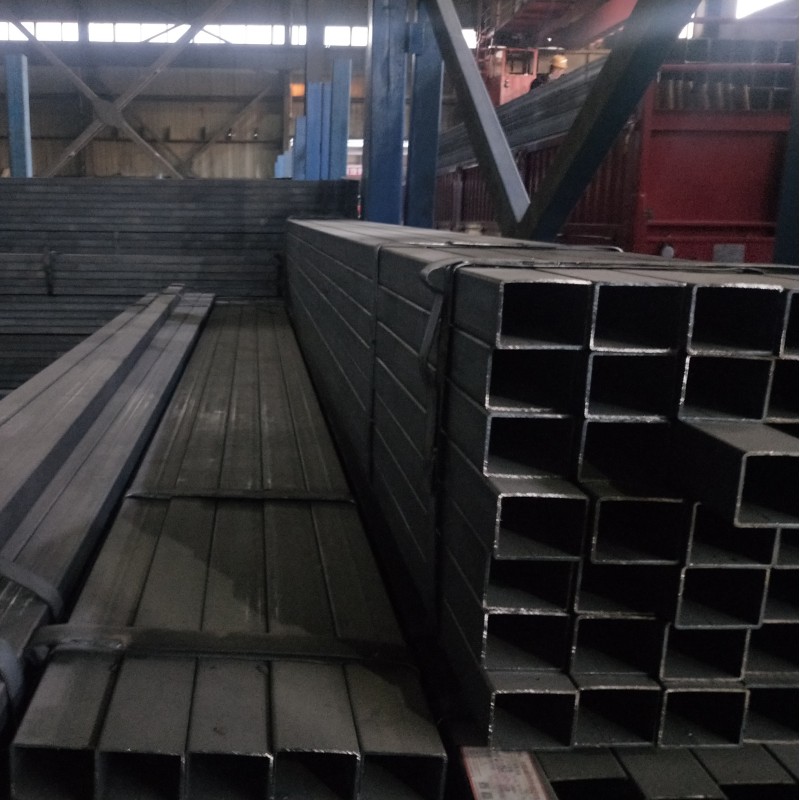

Size:20*20-500*500mm

Thickness:1.3-40mm

Length:5.8m/6m/12m

Product Specification

Specification | Size | 20*20-500*500mm or as the requirement |

Thickness | 1.3-40mm or as the requirement | |

Length | 5.8m/6m/12m or as the requirement | |

Technique | ERW, SSAW, LSAW, galvanized, etc. | |

Steel grades | ASTM A500, ASTM A501, EN10219, EN10210, JIS G3466, CSA G40.21 50W / 350W, AS 1136, AH36, DH36, ASTM A572 Gr50 , ASTM A513, etc. | |

Application |

| |

Package | in the bundle, or wrapped with waterproof cloth as per the customers' requirement | |

Delivery Time | 5-10 days if stock is available; 20-25 days for new production | |

Loading Port | Xingang, Tianjin, China | |

MOQ | 10 tons | |

Others | 1. All the pipes are high-frequency welded. | |

2. Both inner and outer welded stabs can be removed. | ||

3. Pipe can be necked down and punched holes. | ||

4. Supplying BV or SGS Inspection if the client needs it. | ||

Hot rolling of tubes is a manufacturing process used to produce seamless steel tubes with high dimensional accuracy and a smooth surface finish. In this process, a cylindrical billet of steel is heated to a high temperature and then passed through a series of rolls, each of which reduces the thickness and increases the length of the tube. The process can be repeated several times to achieve the desired size and shape. Hot rolling is often used for large-diameter tubes and in applications where mechanical properties are critical, such as in the oil and gas industry.

Our company: