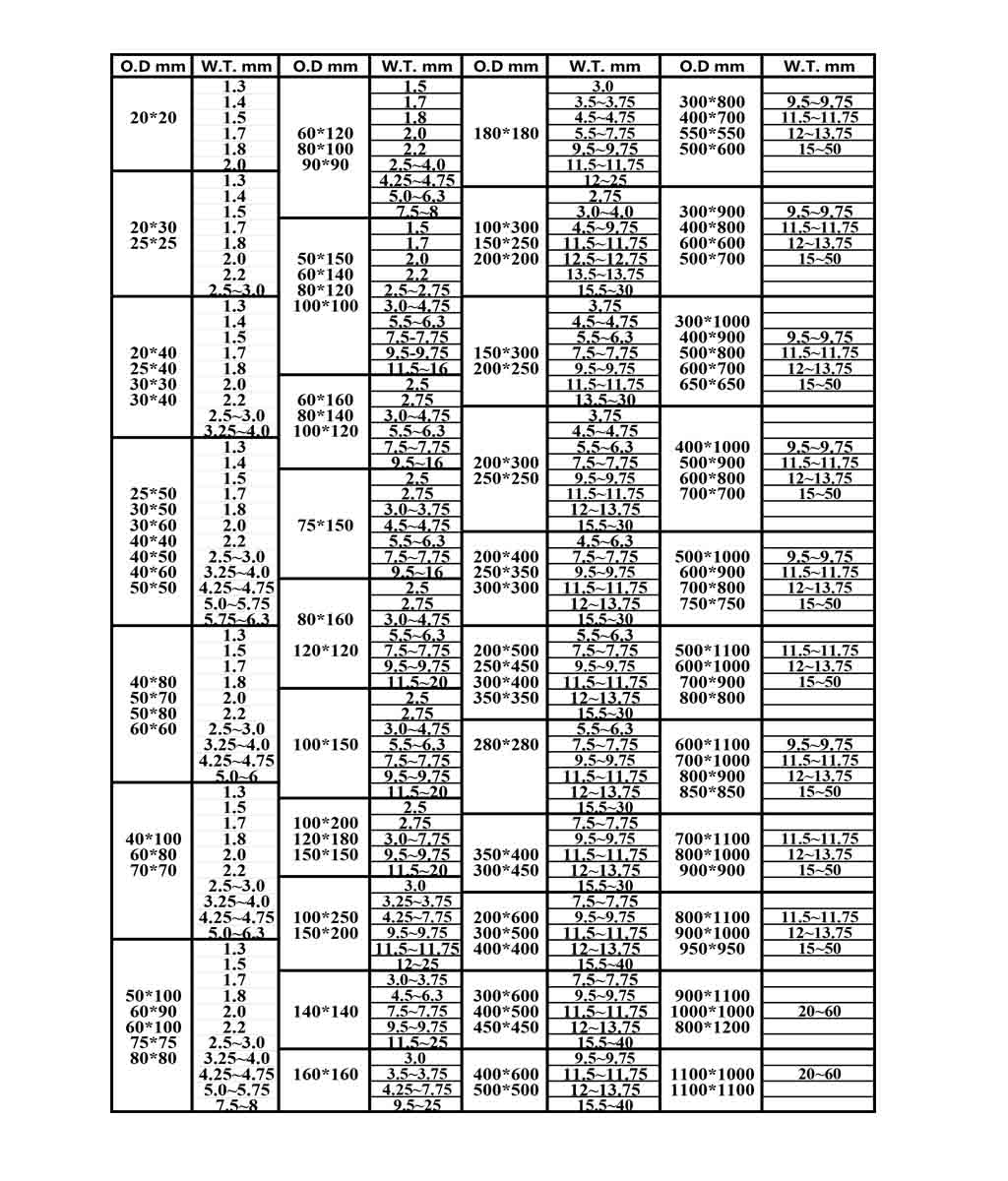

Outer diameter: square: 10*10-1000*1000mm

rectangular: 10*15 800*1100mm or as requirements

Thickness: 0.5-60mm

Length:3-12m according to client requirement

Zinc coating:210g/m2~700g/m2

1. All the pipes are high-frequency welded.

2. Both inner and outer welded stabs can be removed.

3. The pipe can be necked down and punched holes.

4. Supplying BV or SGS Inspection if the client needs it.

Product Description

Hot-dip galvanizing is a widely recognized method for protecting steel from corrosion, and when applied to square and rectangular tubes, it offers superior performance in a range of applications.Their manufacturing process, properties, applications, and benefits are as below.

Manufacturing Process

The manufacturing process of hot-dip galvanized square and rectangular tubes begins with the creation of the tube from steel coils. The coils are first formed into tubes by cold rolling or hot rolling processes and then cut to the desired length. The tubes are then cleaned to remove any impurities, which is crucial for a strong bond between the steel and the zinc coating.

Next, the tubes are submerged into a bath of molten zinc. The temperature of the zinc bath is critical, typically maintained between 450°C and 480°C. The immersion time and the temperature determine the thickness of the zinc coating. Once coated, the tubes are cooled and then passivated to prevent white rust formation.

Properties

Hot-dip galvanized square and rectangular tubes possess several desirable properties that make them suitable for various applications. These include:

· Corrosion Resistance: The zinc coating offers excellent protection against corrosion, making the tubes ideal for outdoor use and in environments where rusting is a concern.

· Durability: The zinc coating can last for decades without maintenance, depending on the thickness of the coating and the environment.

· Flexibility: These tubes can be bent, cut, and welded without compromising the integrity of the zinc coating.

· Aesthetic Appeal: The smooth, shiny finish of the zinc coating adds a visually appealing aspect to constructions and designs.

Applications

Hot-dip galvanized square and rectangular tubes are used in numerous applications due to their strength, durability, and resistance to corrosion. Some of the common applications include:

·Construction: They are used in the construction of buildings, bridges, and scaffolding.

· Automotive: Used for chassis, exhaust systems, and other structural components.

· Agriculture: Ideal for fencing, livestock handling, and irrigation systems.

· Fencing: Popular in residential and commercial fencing for its durability and low maintenance.

· Utility Poles: Used in the construction of transmission towers and utility poles, ensuring long-term performance.

Benefits

The benefits of using hot-dip galvanized square and rectangular tubes are numerous:

· Longevity: The zinc coating significantly extends the life of the steel, reducing the need for replacement.

· Cost-Effective: Although the initial cost is higher than untreated steel, the long-term savings in maintenance and replacement make it a cost-effective choice.

· Environmental Friendliness: Zinc is a recyclable material, contributing to sustainability efforts.

· Safety: The corrosion resistance ensures structural integrity over time, which is critical in safety-sensitive applications.

In conclusion, hot-dip galvanized square and rectangular tubes are an excellent choice for applications where corrosion resistance and durability are paramount. Their versatility in manufacturing and adaptability in various environments make them a preferred material in the construction and engineering industries.

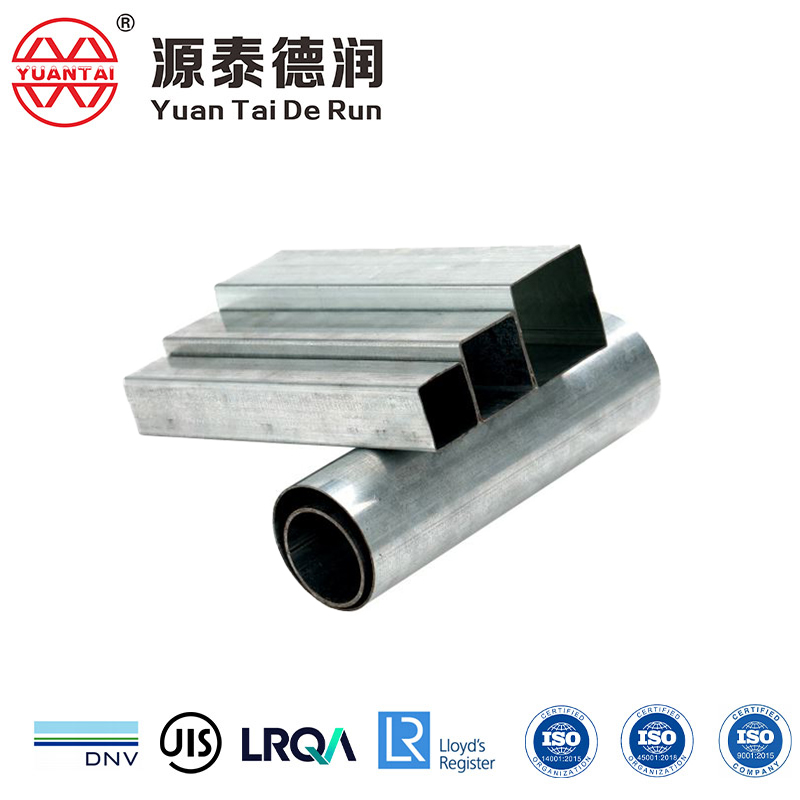

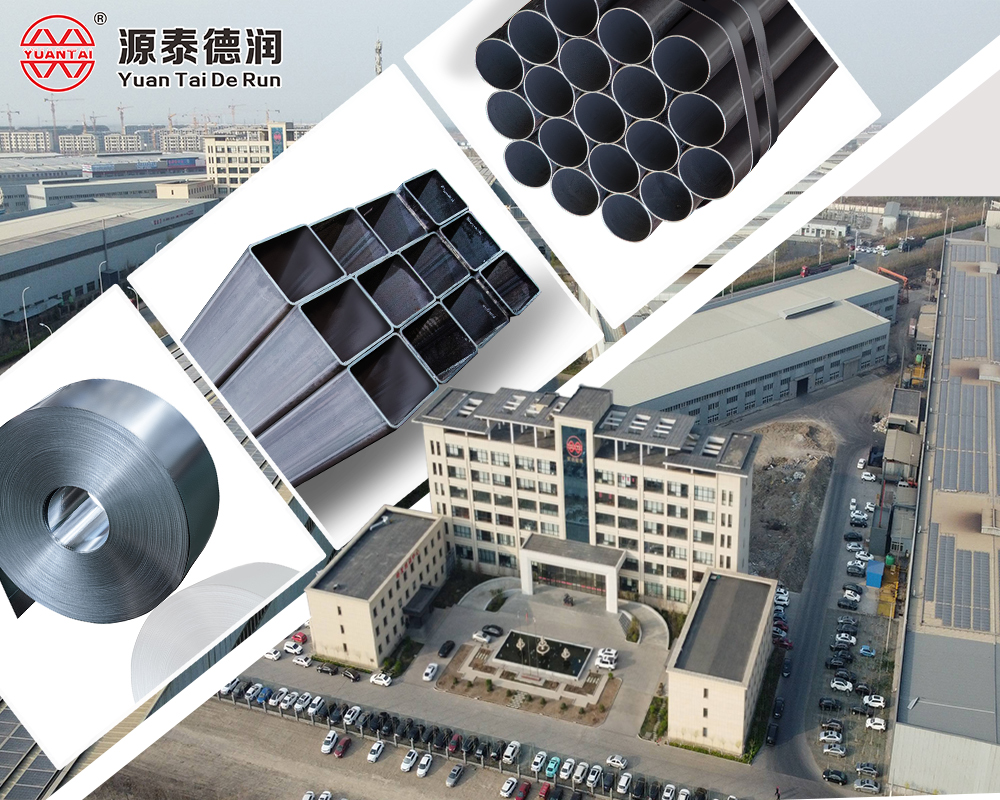

Tianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd. includes 10 subsidiaries. It deserves a large united enterprise group with a registered fund of USD 65 million and fixed assets of USD 3.5 billion. Yuantai Derun is a professional manufacturer of hollow sections, ERW pipe, galvanized pipe and spiral pipe in China and is one of "The top 500 manufacturing enterprises” in China, annual output reaches 10 million tons.

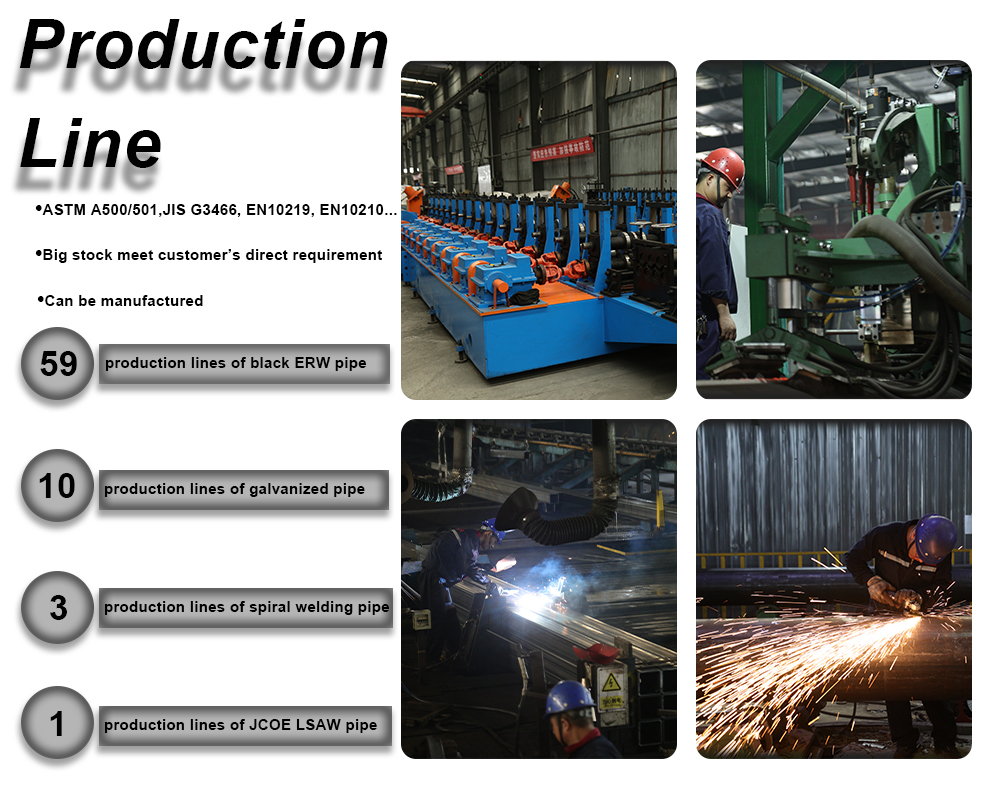

Yuantai Derun has 7 production plants including 59 production lines of black ERW pipe, 10 production lines of galvanized pipe, 3 production lines of spiral welding pipe,1 production lines of JCOE LSAW pipe. Total plants area covers 900 acres.Square pipe from 10*10*0.5mm~1000*1000*60mm, rectangular pipe from 10*15*0.5mm~1000*1100*60mm, Circular pipe from 3/4”x0.5mm~80”x40mm,LSAW steel pipe from Ø355.6~Ø2032mm,spiral pipe from Ø219~Ø2032mm, can be manufactured. Yuantai Derun can manufacture square rectangular pipe as per standards of ASTM A500/501,JIS G3466, EN10219, EN10210,AS1163.

Yuantai Derun has the biggest square rectangular pipe stock in China which can meet customer’s direct procurement requirement. Years of technology accumulation makes Yuantai Derun possessing a wealth of production experience which can greatly shorten the development and production cycle of non-standard steel pipe and speed up the delivery time of customized products. At the same time Yuantai Derun also pays attention to advanced technology research and production use of advanced equipment, the production lines of 500*500mm, 300*300mm and 200*200mm are the most advanced equipment in China which can realize the electronic-controlling automation from the forming to the finishing.

Advanced production equipment, superb technical force, excellent managing talents and solid financial strength guarantee the excellent pipe manufacturing. The products are widely used in many fields, including steel structure of building,automobile manufacture, shipbuilding, machinery manufacturing, bridge construction, container keel construction, stadiums construction, and large airport constructions. The products were used in China famous projects such as the National Stadium (The Bird's Nest), the National Grand Theater and the HongKong-Zhuhai-Macao Bridge. Yuantai products are widely exported to Middle East, Southeast Asia, European Union, Africa, Latin America, USA etc.

Yuantai Derun had obtained the certificates of ISO9001-2008 International Quality Management System and EU CE10219 system. Now Yuantai Derun is striving to apply for “National Well-known Trademark”.