DNV-approved steel mill

DNV-approved hollow section mill

DNV-approved steel square tube mill

DNV-approved steel tube mill

Tianjin Yuantai Derun Pipe Manufacturing Group Co.,Ltd. Industrial area, Daqiuzhuang town, Tianjin city, China

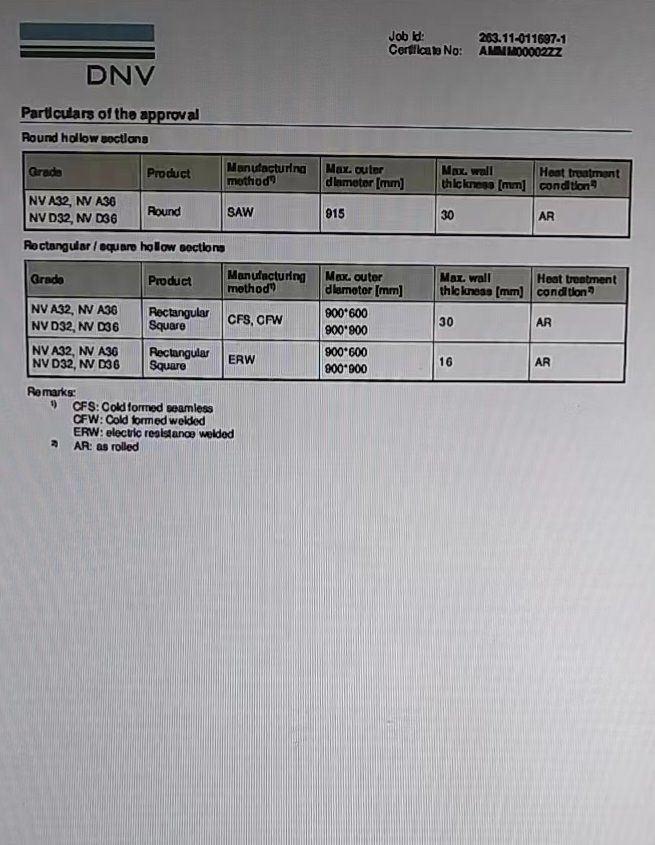

Is an approved manufacturer of Steel hollow sections

In accordance with DNV rules for classification – ships

Certificate No.: AMMM00002ZZ

Steel quality: AH36 STEEL AH36 Hollow Section AH36 Steel square tubes

What steel is used for shipbuilding?

Plain carbon and mild steel are the most common grades of steel for shipbuilding, as they boast a raft of beneficial properties that make them uniquely suited for marine engineering. These include: High yield strengths and typical tensile strengths in a range of 490 – 620 Mpa

What are AH36's Mechanical properties?

Tensile: 70 to 90 ksi ( 482.65MPA to 620.55MPA)

Yield: 51 ksi min (355MPA min)

Elongation: 17 min in 8” 20 min in 2”

Charpy Requirements (LCVN):

AH36: 25 ft/lbs @ 32°F

DH36: 25 ft/lbs @ -4°F

EH36: 25 ft/lbs @ -40°F

Why Yuantai Group?

We provide AH36 DH36 EH36/40 FH36 high-strength shipbuilding steel hollow sections which are used in shipbuilding and other marine applications,

Yuantai Derun Group is one of the leading shipbuilding steel hollow section manufacturing companies in China, which owns 1/2 production lines to produce 500*500 shipbuilding steel hollow sections made from coils directly in China, owns unique advanced technology to produce shipbuilding steel hollow sections sizes max to 1000*1200mm with a number of patented technologies, in order to meet the growing demand of abroad shipbuilding customers, Yuantai has set up special funds to develop special specifications molds, those of which is not popular in the domestic market. Almost all of the shipbuilding steel hollow section sizes production can be completed in Yuantai, which reduces the cost of customer procurement, improves the delivery speed, and improves the satisfaction of the end-users of hollow sections.

2008~2021 China shipbuilding steel consumption

Years | shipbuilding steel consumption | Increase in value over the previous year | Sections | ||

(10000tons) | (%) | plates | beams | others | |

2012 shipbuilding steel consumption | 1200 | -29.4 | 1055 | 105 | 40 |

2013 shipbuilding steel consumption | 1100 | -8.3 | 900 | 110 | 90 |

2014 shipbuilding steel consumption | 1300 | 18.2 | 1050 | 145 | 105 |

2015 shipbuilding steel consumption | 1200 | -7.7 | 900 | 110 | 90 |

2016 shipbuilding steel consumption | 1150 | -4.2 | 870 | 90 | 80 |

2017 shipbuilding steel consumption | 800 | -30.4 | 650 | 70 | 65 |

2018 shipbuilding steel consumption | 850 | 6.3 | 700 | 77 | 73 |

2019 shipbuilding steel consumption | 880 | 3.5 | 725 | 80 | 75 |

2020 shipbuilding steel consumption | 950 | 8.0 | 800 | 80 | 70 |

2021 shipbuilding steel consumption | 980 | 3.2 | 820 | 90 | 70 |