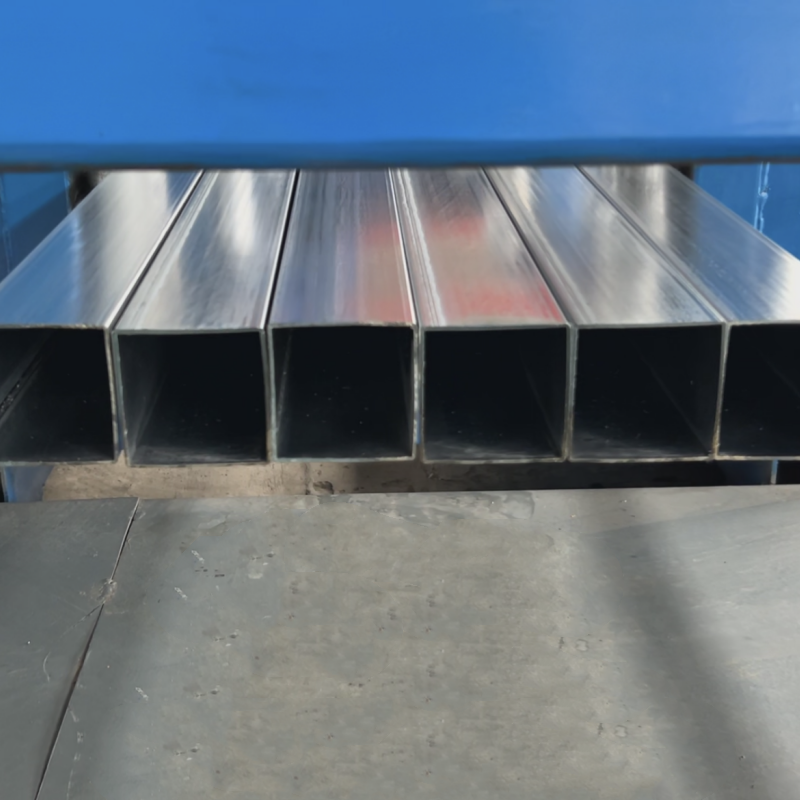

Outer Diameter: SHS:20×20-200×200mm RHS:20×30-100×200mm CHS:20-203mm

Thickness: 0.8-3.0mm

Length: 0.5-24M

Product Details:

Outer Diameter | SHS:20×20-200×200mm RHS:20×30-100×200mm CHS:20-203mm |

Thickness | 0.8-3.0mm |

Length | 0.5-24M |

MOQ | 2-5 Tons |

Payment method | TT/LC |

Delivery time | 7-35 days |

Capacity | 3 million tons/year |

Port of shipment | Tianjin Xingang Port |

Grade | S350GD |

Zinc, aluminum, and magnesium rectangular tube is a popular material used in various applications due to its many advantages. One of the main benefits of this material is cost savings. The zinc, aluminum, and magnesium coating is applied to the base material using a continuous galvanizing process, which reduces the need for post-processing and lowers labor costs.

Another advantage of zinc, aluminum, and magnesium materials is their self-healing ability. The coating forms a dense protective film composed of zinc hydroxide, alkaline chloride zinc, and magnesium hydroxide near the cut or scratch location during use. This protective coating exhibits good adhesion, high density, and low conductivity, effectively separating the external corrosion medium from the bare metal substrate, thereby inhibiting further corrosion of the cut or scratched location by external factors. The neutral salt spray test for zinc, aluminum, and magnesium material currently reaches 4440 hours without any red rust.

In addition to these advantages, zinc, aluminum, and magnesium material possess superior anti-corrosion and anti-rust properties, making them ideal for outdoor and marine applications. It also possesses excellent wear resistance and high-strength properties, making it suitable for structures that require durability and strength.

Overall, the many advantages of zinc, aluminum, and magnesium rectangular tubes make it a popular choice for various applications in the construction, manufacturing, and automotive industries. Its self-healing ability, low cost, and superior corrosion and wear resistance properties make it an excellent choice for any project that requires a durable and long-lasting material.

Our company: