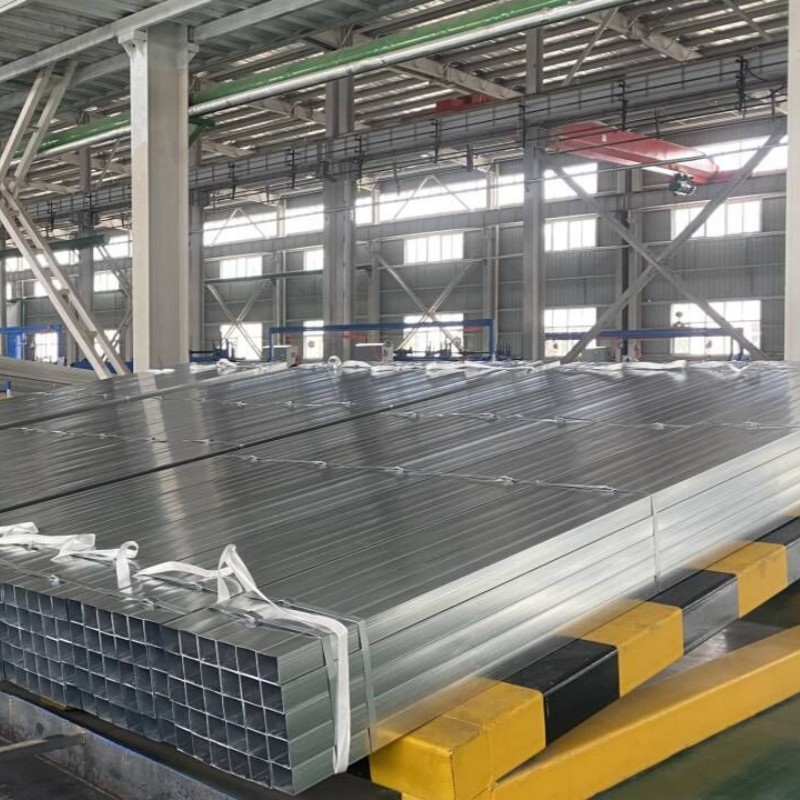

Square ZAM steel coating tube: 20×20-200×200mm

Rectangular ZAM steel coating tube: 20×30-100×200mm

Round ZAM steel coating pipe: 20-203mm

Thickness: 0.8-3.0mm

Length: 0.5-24M

Product Details:

Outer Diameter | SHS:20×20-200×200mm RHS:20×30-100×200mm CHS:20-203mm |

Thickness | 0.8-3.0mm |

Length | 0.5-24M |

Product material | 51D 52D 53D 300 340 400 420 440 490 570 ASTM A 1046 JIS G 3323-2012 EN10324 |

Coating weight | ZM20~ZM400 |

MOQ | 2-5 Tons |

Payment method | TT/LC |

Delivery time | 7-35 days |

Capacity | 3 million tons/year |

Port of shipment | Tianjin Xingang Port |

Zinc alloy

Zinc alloy has a low melting point, good fluidity, and is easy to weld. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. Cast zinc alloy has good fluidity and corrosion resistance, and is suitable for die-cast instruments, automobile parts casings, etc. Deformed zinc alloy has good plasticity and ductility and is mainly used as battery casings, printed boards, roof panels, and daily hardware. The output of cast alloys is much greater than that of deformed alloys. For structural parts of fast-moving consumer goods, deformed alloys are rarely used. Therefore, the following article will only focus on die-cast zinc alloy.

The density of zinc alloy is 6.3~6.7g/cm, the tensile strength σb is 280~440MPa, and the melting point is low. It melts at 385°C and is easy to die-cast.

Zinc alloy has the largest specific gravity among the four alloys described in this article, and has the best fluidity. It has good casting performance and can die-cast precision parts with complex shapes and thin walls, and the surface of the castings is smooth. Among the products I designed, the thinnest wall thickness of zinc alloy die-casting parts is only 0.4mm.

At room temperature, zinc alloy has good strength. It should be noted that zinc alloy is not suitable for use in high and low temperature (below 0°C) working environments. Zinc alloy has good mechanical properties at room temperature. However, the tensile strength at high temperatures and the impact properties at low temperatures decrease significantly. Zinc alloys have poor corrosion resistance. When the impurity elements lead, cadmium, and tin in the alloy components exceed the standards, the castings will age and deform. Zinc alloy die castings have aging effects and aging phenomena, that is, their strength naturally decreases and becomes brittle after a long time. This is why many people complain that when replacing zinc alloy faucets, brittle fracture often occurs, causing the threaded part of the faucet to remain in the water pipe and not be removed.

Our company: