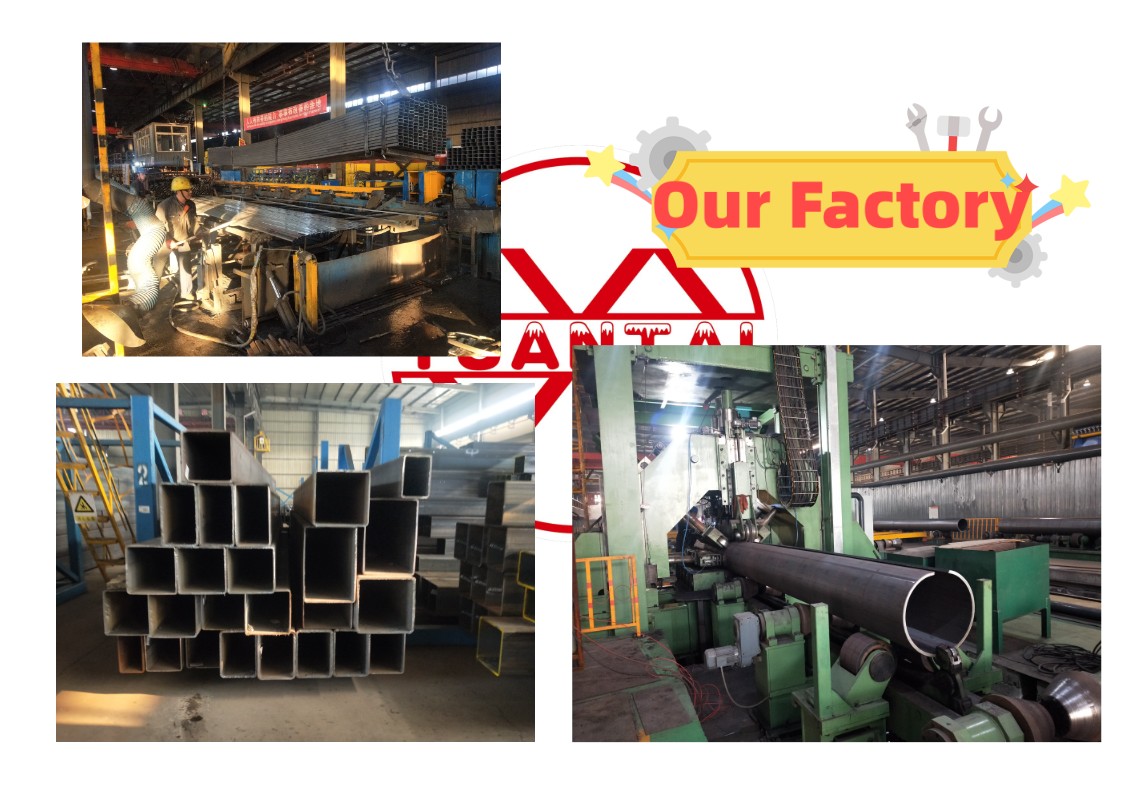

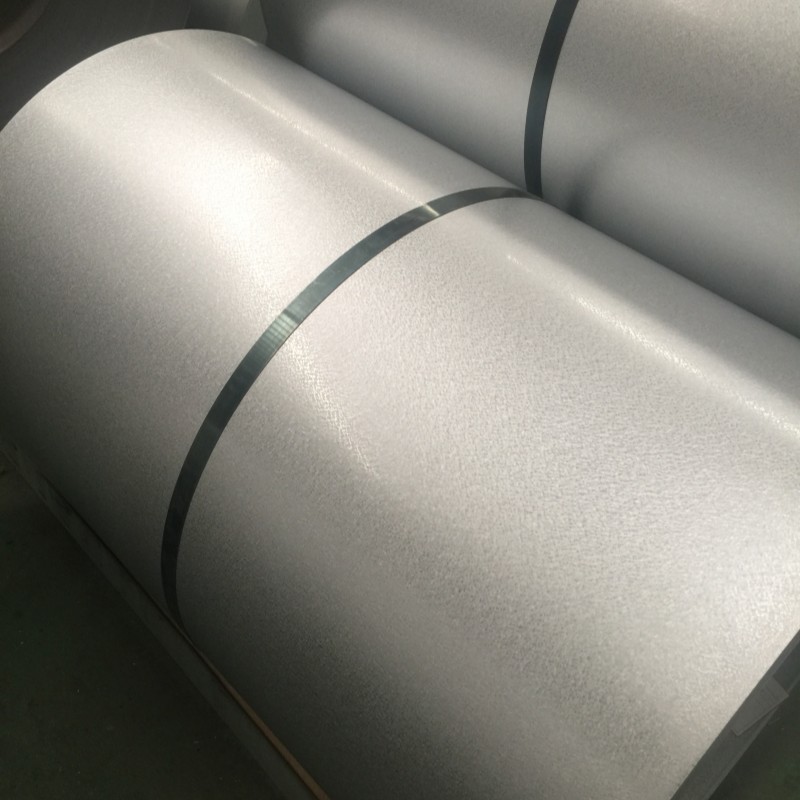

Width: 900-1250mm

Wall Thickness: 0.25-1.5mm

Material quality: SCS51D+ ZM275,350GD

Product Details:

Width | 900-1250mm |

Wall Thickness | 0.25-1.5mm |

Material | 51D 52D 53D 300 340 400 420 440 490 570 ASTM A 1046 JIS G 3323-2012 EN10324 |

Process | Ordinary processing or customized processing |

Origin | Tianjin, China |

Payment Method | TT/LC |

Delivery Time | 7-60 days |

Port | Tianjin Xingang Port |

There are several reasons why the corrosion resistance coefficient of zinc, aluminum, and magnesium can be improved:

1) Adding magnesium to the zinc bath can reduce the intergranular corrosion rate and improve the corrosion resistance of the coating. This explanation is mainly for the low Mg content (0.2%), which can refine the grains and strengthen the grain boundaries.

2) Increase the electrode potential of the substrate. With the addition of magnesium, the corrosion potential of the zinc-based alloy shifted positively, and the corrosion current decreased significantly. Some researchers believe that after adding Mg to the zinc-aluminum coating alloy, the corrosion potential does not change much, but the AC impedance increases and the double-layer capacitance of the electrode decreases, that is, the corrosion reaction is delayed, thereby improving the electrochemical corrosion resistance of the coating.

3) The addition of magnesium promotes the formation of stable dense corrosion products on the coating surface and improves the corrosion resistance energy of the coating. Densification of this corrosion product suppresses the diffusion of oxygen, so corrosion resistance can be improved. However, there is a different opinion on the corrosion products of the dense layer

4) Buffering effect after Mg dissolves Mg can lower the pH value of the cathode, hinder the formation of ZnO, and inhibit the reduction of oxygen. Many researchers believe it has more protective properties than alkaline zinc carbonate.

The excellent corrosion resistance of zinc-aluminum-magnesium coatings is universally recognized, but there are different explanations for the reasons why the corrosion resistance of zinc-aluminum-magnesium alloys can be improved. The mechanism for improving Zn-Al-Mg corrosion resistance can be a combination of mechanisms rather than relying on only one corrosion mechanism.

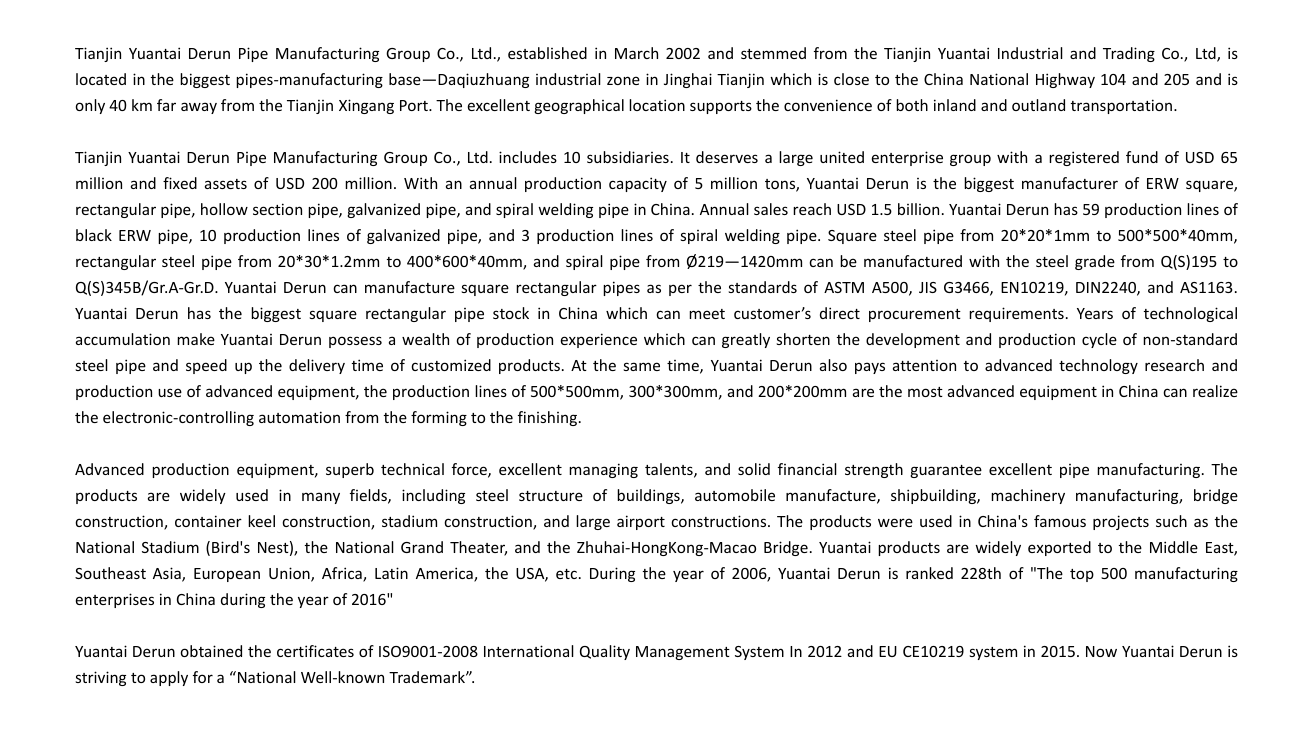

Our company: