Thickness:1.3-40mm

Length:5.8m/6m/12m

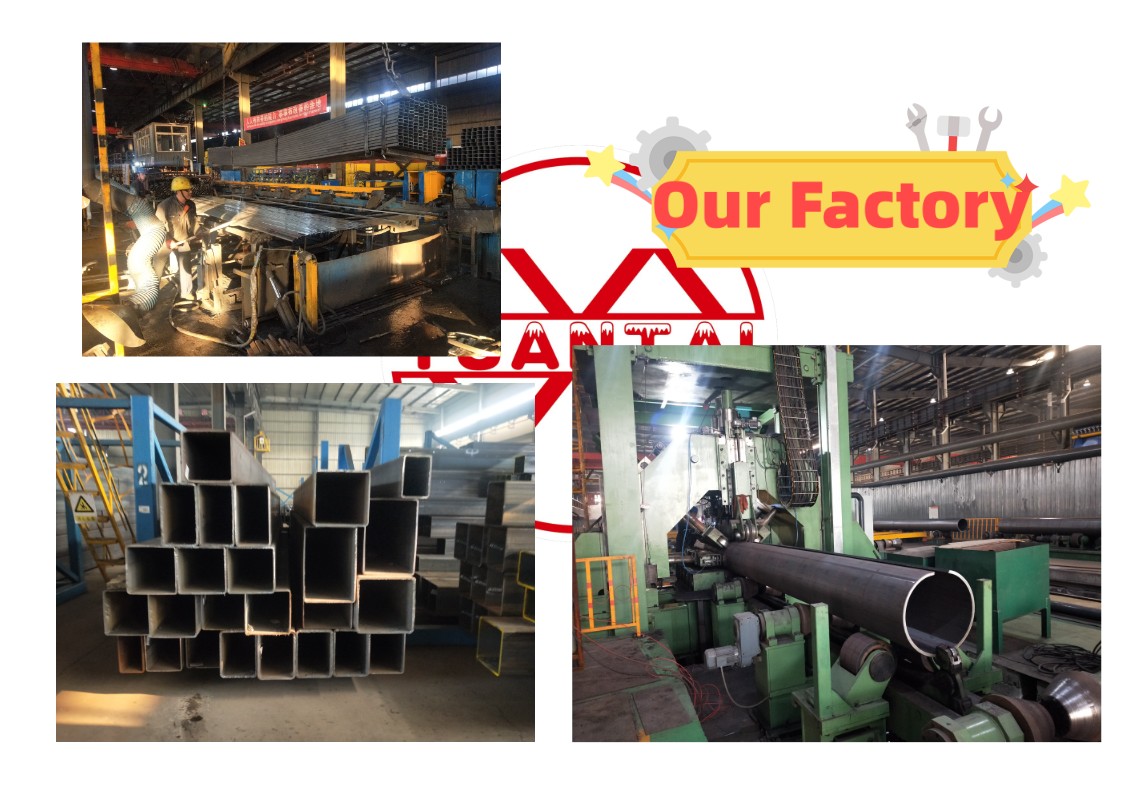

Steel square tube is an important building material used in a wide range of industries. The manufacturing process of steel square tubes involves various stages and requires skilled labor and advanced machinery. Despite the challenges, this process is highly efficient and results in a durable and reliable product.

The first step in the manufacturing process of steel square tubes is obtaining raw materials. High-quality steel billets are selected based on their material properties, such as strength and durability. These billets are then heated to a specific temperature and rolled into thin sheets.

Next, the sheets are processed through a cold-forming process. This process involves bending the steel sheets into a square shape, using a special machine. The edges of the square are then welded together to form a tube. The welding process is carefully monitored to ensure that the tube is seamless and free from defects.

Once the tube is formed, it is then passed through a series of finishing processes. The tube is trimmed to the desired length and the ends are cut to conform to the required specifications. The tube is also polished and coated to prevent it from rusting or corroding.

Finally, the steel square tube is subjected to a series of rigorous quality control checks to ensure that it meets the required standards. Any defects are identified and corrected before the tube is approved for use.

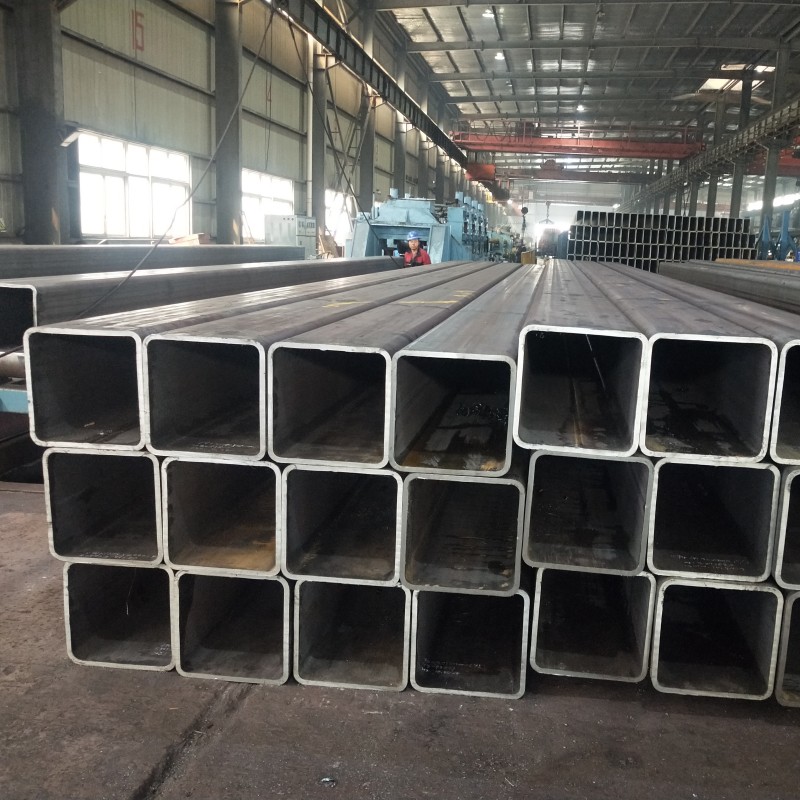

Product Specification

Size | 300*300-1000*1000mm |

Thickness | 1.3-40mm |

Length | 5.8m/6m/12m |

Technique | ERW |

Material Grade | Q195,Q215,Q235B,Q355B, |

Application | Construction structure, kingpost, hard-core items, automotive frame steel, etc. |

Package | in the bundle, or wrapped with waterproof cloth as per the customers' requirement |

Delivery Time | 20-25 days |

Loading Port | Xingang, Tianjin, China |

MOQ | 10 tons |

1. All the pipes are high-frequency welded. 2. Both inner and outer welded stabs can be removed. 3. Supplying BV or SGS Inspection if the client needs it. | |

Our company: