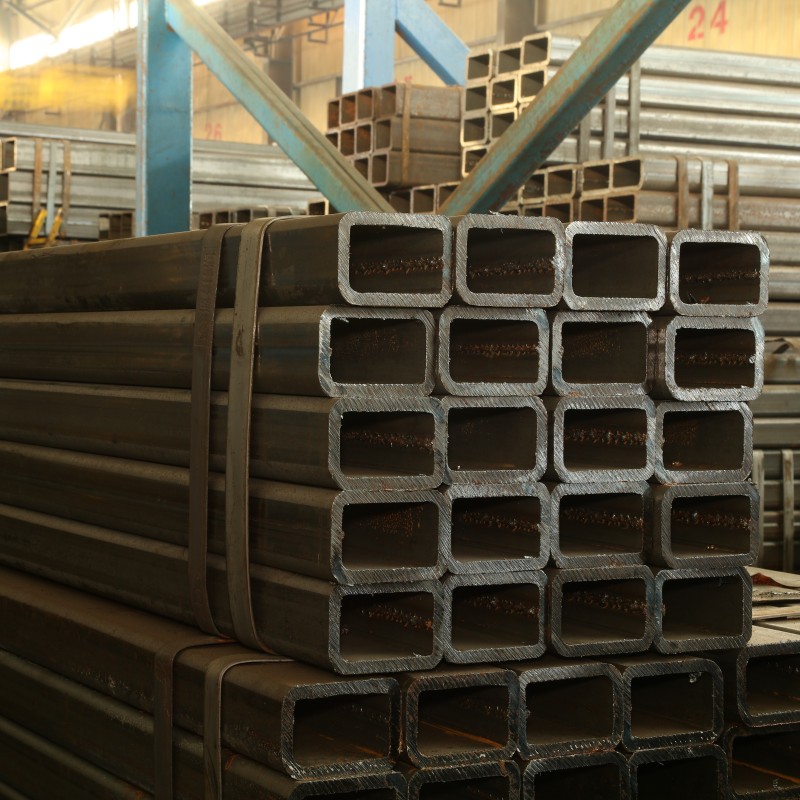

Size: 20*20-500*500mm or as the requirement,

large size steel tube above 500*500 can be produced.

Thickness: 1.3-40mm or as the requirement

Length: 5.8m/6m/12m or as the requirement

The production process of square tubes and square tubes includes preparation, cutting and adjustment, bending and forming, welding and connection, surface treatment, and quality inspection. Each stage requires professional equipment and tools, and control parameters to ensure product quality and stability. As a common metal product, square tubes have been widely used in construction, machinery, transportation, aerospace, and other fields.

The production process mainly includes the following steps:

In the preparation stage, the raw materials of square tubes or rectangular tubes need to be inspected and controlled to ensure that the quality of the raw materials meets the production requirements. At the same time, according to production needs, various production equipment and tools are prepared, and necessary adjustments and inspections are made to ensure the normal operation of the equipment.

The cutting and adjustment stage is a very critical step in the production of square tubes and square tubes. According to production specifications and requirements, professional cutting equipment and tools are used to accurately cut the raw materials of square tubes or rectangular tubes to ensure that the length and shape of each section of raw materials meet the requirements. At the same time, necessary adjustments and corrections are made to the cut materials to ensure the normal progress of subsequent processing.

In the bending and forming stage, professional bending equipment and tools are needed to accurately bend and form the square tube or rectangular tube according to production requirements. In the process of bending and forming, it is necessary to master the quality of the material, bending radius, bending speed, and other parameters to avoid cracks, deformation, and other problems.

The connection of square tubes and square tubes is usually completed by welding. In the welding and connection stage, professional welding equipment and tools are needed to select appropriate welding methods and technical parameters according to different materials and production requirements to ensure the quality and stability of welding. At the same time, necessary inspection and control are required to avoid welding defects and errors.

The surface treatment stage is a very important step in the production of square tubes and rectangular tubes. In the surface treatment stage, it is necessary to select appropriate surface treatment methods and technical parameters according to different requirements, such as spraying, electroplating, baking paint, etc. At the same time, necessary inspection and control are required to ensure the quality and stability of surface treatment.

The quality inspection and control stage is an indispensable step in the production of square tubes and rectangular tubes. In the quality inspection and control stage, comprehensive inspection and control are required to ensure that the quality and stability of the final product meet the requirements. At the same time, the production process and technical parameters need to be adjusted and controlled according to the inspection results to improve production efficiency and product quality.

Size | 20*20-500*500mm or as the requirement, large size steel tube above 500*500 can be produced. |

Thickness | 1.3-40mm or as the requirement |

Length | 5.8m/6m/12m or as the requirement |

Steel grades | ASTM A500, ASTM A501, BS 1387, EN10219, EN10210, ASTM A53, JIS G3466, GB/T9711, GB/T3094, GB/T3091, GB/T6728 |

Application | Steel Frame Glass Curtain Wall Heavy steel structure Aerospace engineering High-speed rail Shipbuilding Seamless steel pipe for machinery Seamless steel pipes for automobiles and high-speed trains Seamless steel pipes for the chemical industry and boilers Seamless steel pipe for bridges |

Package | in the bundle, or wrapped with waterproof cloth as per the customers' requirement |

Delivery Time | 7-30 days |

Loading Port | Xingang, Tianjin, China |

MOQ | 10 tons |

1. All the pipes are high-frequency welded. 2. Both inner and outer welded stabs can be removed. 3. Pipe can be necked down and punched holes. 4. Supplying BV or SGS Inspection if the client needs it. | |